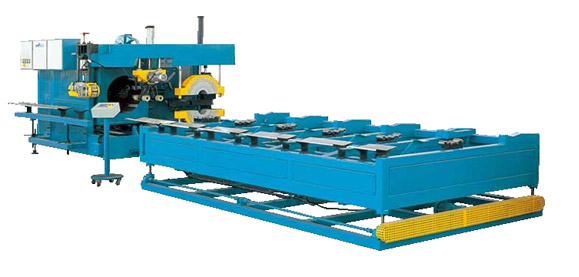

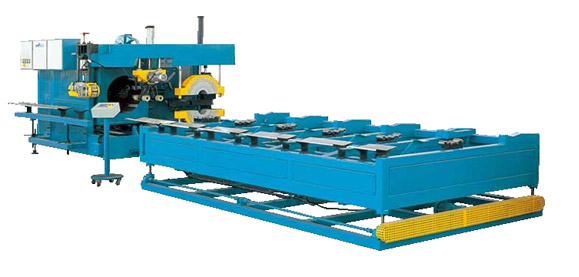

18 Years Factory Screw Mixer Design - Film Die Series – Jwell Detail:

Film Die Series

Product detail pictures:

Related Product Guide:

Natvar introduces tight-tolerance, micro-extruded thermoplastic medical tubing line | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Extruding Machines Market, Share, Growth, Trends and Forecast to 2023: Market Study Report | Производственная Линия Ppr

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for 18 Years Factory Screw Mixer Design - Film Die Series – Jwell, The product will supply to all over the world, such as: Chile , Washington , Estonia , Now we've been sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We have been ready to share win-win corporation.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

-

Hot Sale for Refrigerator Door Gasket Cutting M...

-

Wholesale Dealers of Double Screw Polystyrene F...

-

OEM Supply Plastic Link Bar Pvc Coextrusion - ...

-

Manufactur standard Extruder For Plastic Granul...

-

Good Wholesale Vendors Pe Tube Making Machine -...

-

18 Years Factory Plastic Film Extruder - JWGK ...