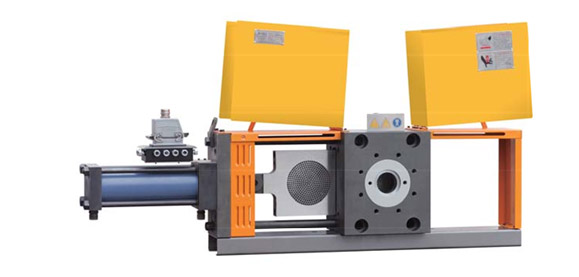

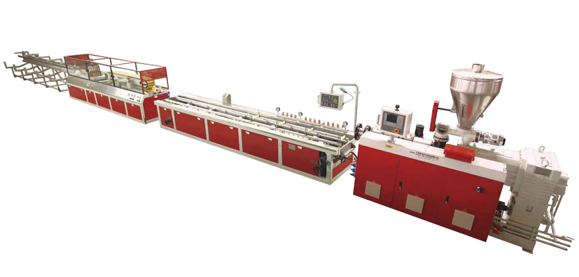

2017 China New Design Screw Barrel For Twin Screw Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

NewAge donates laptops to Cambodian school | Screw Extruder Machine

Global Twin-screw Extruders Market 2018 Sales Revenue Analysis, Major Manufacturers Performance, Industry Share and Forecast 2025 | Производственная Линия Ppr

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for 2017 China New Design Screw Barrel For Twin Screw Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Uruguay , Pretoria , Turkmenistan , We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

-

100% Original Factory Pvc Pipe Extrusion Line -...

-

Cheap price Polyamide Strip Machine - WPC pell...

-

Factory supplied Small Plastic Extruders For Sa...

-

New Delivery for Pet Thermoform Sheet Making Ma...

-

Top Suppliers Hydraulic Extruding Machine - Fu...

-

One of Hottest for Pvc Screw Extruding Equipmen...