2017 Latest Design Polystyrene Foam Sheet Extruder - Biaxially Oriented Die – Jwell Detail:

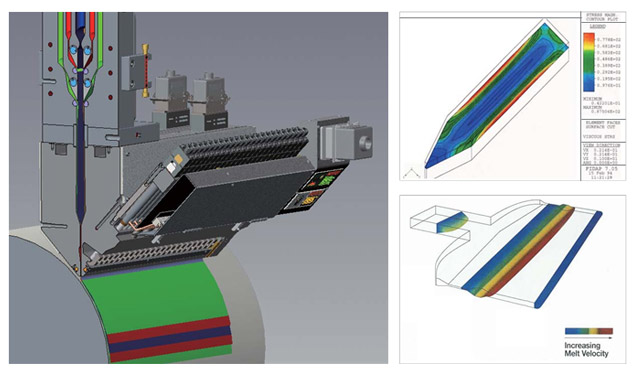

Biaxially Oriented Die

Product detail pictures:

Related Product Guide:

Plastic Compounding Machinery Market 2018 Analysis by Key Developments, Key Players, and Regions Forecast to 2023 | Screw Extruder Machine

Геоинформационные системы для решения диспетчерских и управленческих задач предприятий газовой отрасли // Компании // Аналитика | Производственная Линия Ppr

Our firm sticks on the theory of "Quality will be the life in the enterprise, and status could be the soul of it" for 2017 Latest Design Polystyrene Foam Sheet Extruder - Biaxially Oriented Die – Jwell, The product will supply to all over the world, such as: Netherlands , Brazil , Czech republic , We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

-

Competitive Price for Конический Двухшнековый Э...

-

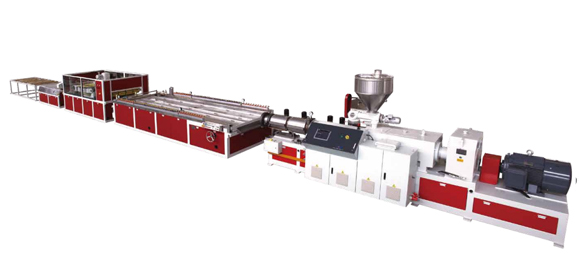

Factory Promotional Wpc Extrusion Machine - La...

-

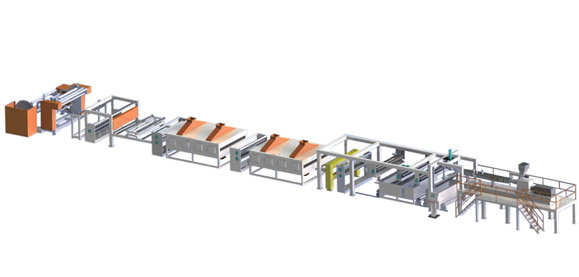

Factory Promotional Wpc Extrusion Machine - Co...

-

Fast delivery Twin Screw Extruder Twin Screw Ex...

-

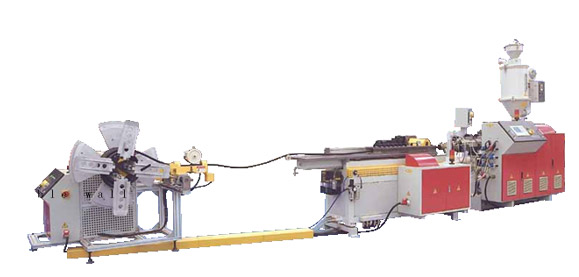

Factory Cheap Plastic Extrusion Single Screw An...

-

Cheap price Single Screw Designed Extruder - S...