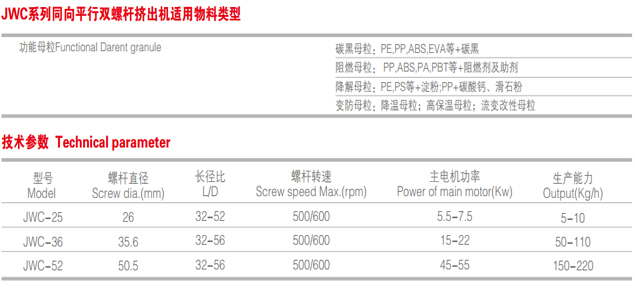

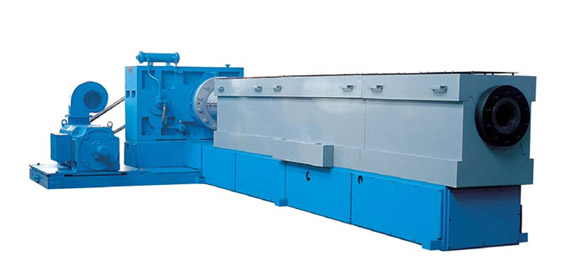

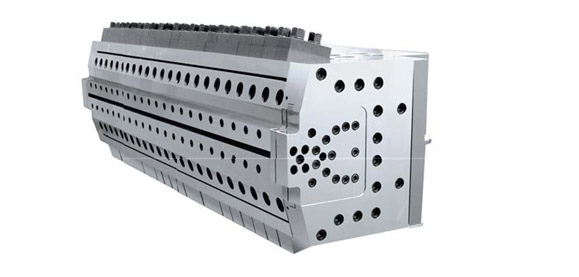

8 Year Exporter Mini Extruder Machine - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Станкосервис: АИС Диспетчер | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Publiscopie : La maîtrise totale des outillages pour l’extrusion thermoplastique | Extruded Plastic Tubing

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for 8 Year Exporter Mini Extruder Machine - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Brunei , Adelaide , Brazil , Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

-

Competitive Price for Plastic Profiles Extrusio...

-

Reasonable price Ppr Water Pipe Extrusion Line ...

-

Ordinary Discount Co-rotating Twin Screw Extrud...

-

Special Design for Tpo Goemembrane Extrusion Li...

-

Big Discount Screw Barrel For Extruder - Twin ...

-

PriceList for Двухшнековая Экструдер Анимация -...