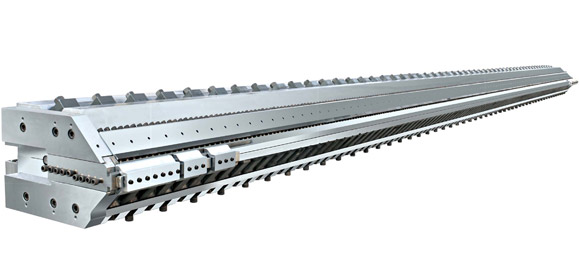

Best-Selling Ppr Extruding Production Line - Film Die Series – Jwell Detail:

Film Die Series

Product detail pictures:

Related Product Guide:

Medical Tubing Packaging Market: An Insight On the Important Factors and Trends Influencing the Market | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

NewAge donates laptops to Cambodian school | Extruded Plastic Tubing

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for Best-Selling Ppr Extruding Production Line - Film Die Series – Jwell, The product will supply to all over the world, such as: Chile , Albania , America , We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers' satisfaction and achieve win-win situation .

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

-

Ordinary Discount Plastic Granule Machine - Ho...

-

Wholesale Discount Sheet Extrusion Machine - T...

-

Fixed Competitive Price Plastic Extruder Machin...

-

Special Design for Single Screw Extruder China ...

-

Factory Price Nitriding Twin Conical Screw Barr...

-

Reasonable price for Extruder Screw Machine - ...