Bottom price Filament Extruding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

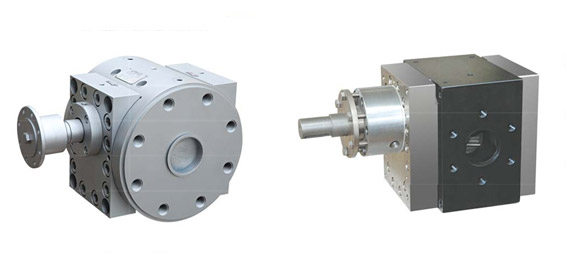

Product detail pictures:

Related Product Guide:

Registration Opens for Extrusion 2018 Conference : Plastics Technology | Extruded Plastic Tubing

| Производственная Линия Ppr

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for Bottom price Filament Extruding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Austria , Swansea , America , We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will probably be more conveniently to service our customers.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

-

Europe style for Gpps Sheet Extrusion Line - P...

-

Discount wholesale Extruder For Plastic Pvc - ...

-

Factory Price Double-layers Extruding Machine -...

-

Hot sale Factory Upvc Windows Materials - GFQ ...

-

Factory Price Двухшнековый Экструдер Pdf - PU/...

-

Best-Selling Co-extrusion Conical Twin Screw Ex...