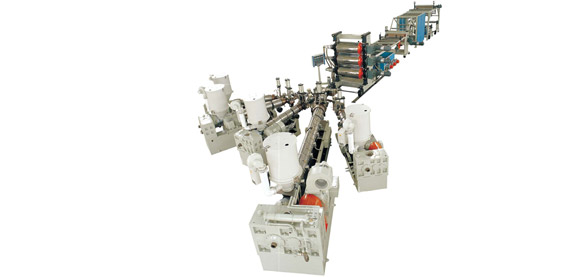

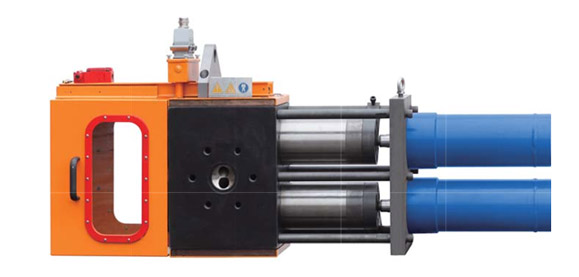

Bottom price Filler Masterbatch Pelletizing Machine - Film Die Series – Jwell Detail:

Film Die Series

Product detail pictures:

Related Product Guide:

25 Years of Change: Industry veterans look back on the past quarter century | Extruded Plastic Tubing

Process Improvements Deliver Taste In Plant-Based Meat | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for Bottom price Filler Masterbatch Pelletizing Machine - Film Die Series – Jwell, The product will supply to all over the world, such as: San Francisco , Panama , Detroit , We aspire to meet the demands of our customers globally. Our range of products and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

-

Personlized Products Plastic Corner Protection ...

-

OEM manufacturer Casement Window Upvc Profile -...

-

Free sample for High Quality 38crmoala Bimetall...

-

Factory Outlets Small Plastic Filament Extruder...

-

Fixed Competitive Price Extrusion Manufacturing...

-

Wholesale Конструкция Пластикового Экструдера -...