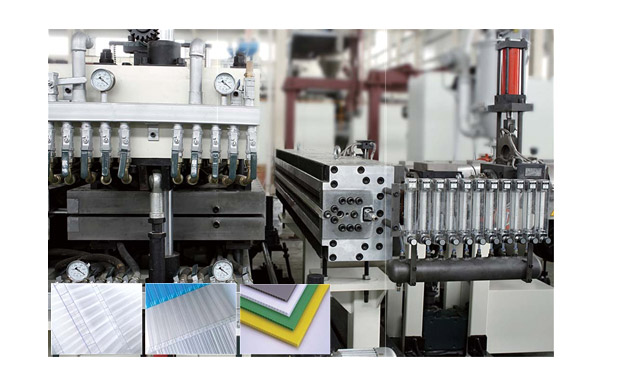

Bottom price Pvc Ceiling Panel Machine - Hollow Cross Section Plate Die Series – Jwell Detail:

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Extrusion specialist talks ‘core’ competencies in medical catheter manufacturing | Производственная Линия Ppr

Extrusion Cooling: It’s All About Turbulence : Plastics Technology | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

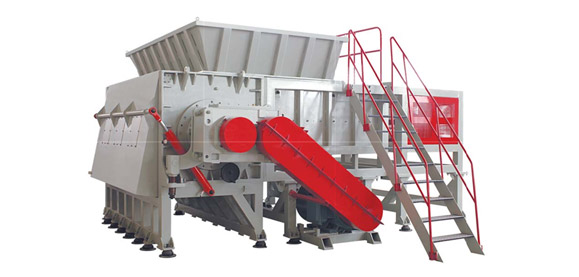

Our firm aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Bottom price Pvc Ceiling Panel Machine - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Uzbekistan , Madagascar , Canada , We have developed large markets in many countries, such as Europe and the United States, Eastern Europe and Eastern Asia. Meanwhile with the powerful predominance in persons with ability, strict production management and business concept.we constantly carry on self-innovation, technological innovation, managing innovation and business concept innovation. To follow the world markets fashion, new products are kept on researching and providing to guarantee our competitive advantage in styles, quality, price and service.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

-

Free sample for High Speed Sheet Plastic Extrus...

-

Rapid Delivery for Sheet Extruder Machine - Co...

-

Professional Design Sj-45 Single Screw Extruder...

-

China Manufacturer for Sheet Machine Producer -...

-

OEM China White Masterbatch For Plastic Extrusi...

-

China Gold Supplier for Zhoushan Plastic Screw ...