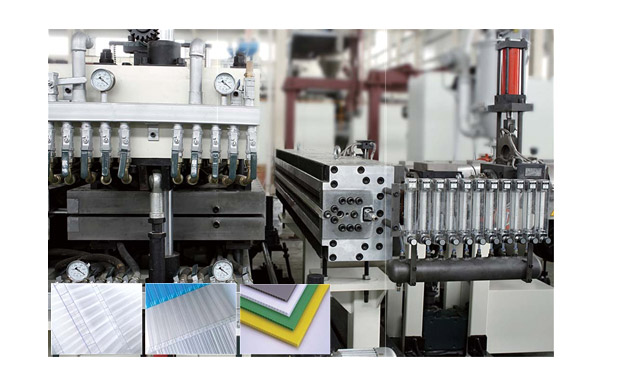

Bottom price Two-stage Single Screw Extruder - Hollow Cross Section Plate Die Series – Jwell Detail:

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Когда у Белорусских цементных заводов откроется второе дыхание | Screw Extruder Machine

Global Plastic Extrusion Machine Market Size is accounted for $xx Billion by 2025 | Производственная Линия Ppr

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for Bottom price Two-stage Single Screw Extruder - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Detroit , Lesotho , Czech Republic , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

-

OEM Factory for Waste Recycling Plant - Film D...

-

Hot Sale for Factory Direct Professional Plasti...

-

High Performance Waste Plastic Processing Machi...

-

18 Years Factory Screw Barrel For Pvc - PVC Hi...

-

Hot Sale for High Performance Screw And Barrel ...

-

Big discounting Устранение Неисправностей При Э...