Cheapest Factory Thermoplastic Extrusion - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

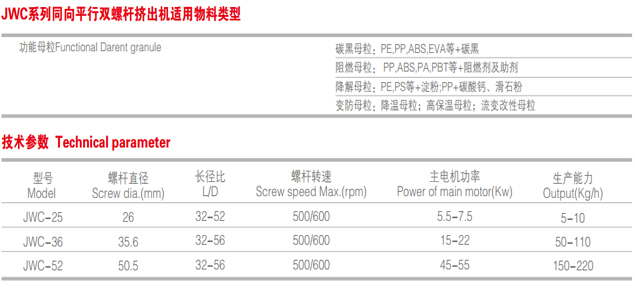

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Global Extruding Machines Market Insights 2018-2025 : Milacron Holdings Corp., Toshiba Machine Co., Ltd., The Japan Steel Works | Wpc Extrusion Machine

A Culture Built on Innovation in Medical Tubing Extrusion : Plastics Technology | Wpc Extrusion Machine

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Cheapest Factory Thermoplastic Extrusion - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Milan , Curacao , San Francisco , To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our merchandise list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're about to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

-

Short Lead Time for 380v Plastic Sheet Extruder...

-

Factory Price For Twin Screw Plastic Pipe Extru...

-

Best-Selling Plastic Recycling Machine - Biaxi...

-

Factory directly supply Small Plastic Extrusion...

-

Factory Promotional Double Layer Physical Foam ...

-

PriceList for Extrusion Machine - Single Layer...