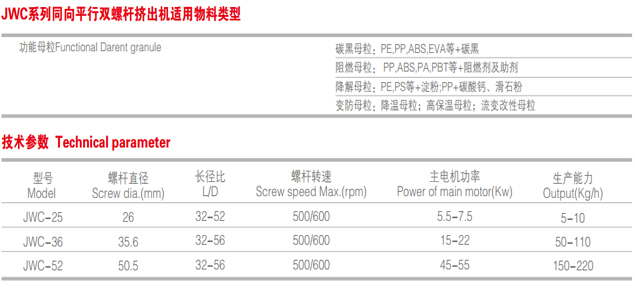

China Factory for Pvc Plastic Roofing Sheet Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

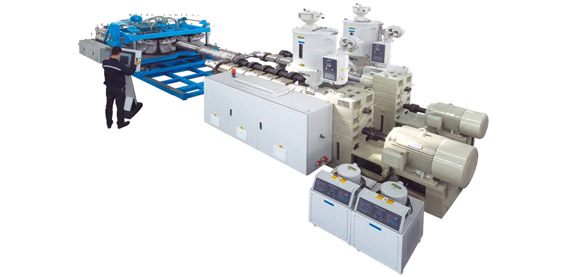

Product detail pictures:

Related Product Guide:

Tubing maker NewAge goes landfill free | Производственная Линия Ppr

25 Years of Change: Industry veterans look back on the past quarter century | Extruded Plastic Tubing

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for China Factory for Pvc Plastic Roofing Sheet Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Oman , Georgia , Sierra Leone , With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

-

Low MOQ for Screw Element - DYPS Series Strong...

-

Good Wholesale Vendors Pvc Pipe Equipment - HD...

-

Well-designed Plastic Bag Film Extrusion Machin...

-

Reliable Supplier Экструзионная Линия Для Произ...

-

factory Outlets for Pp Strapping Straps Machine...

-

Leading Manufacturer for 30mm Single Screw Extr...