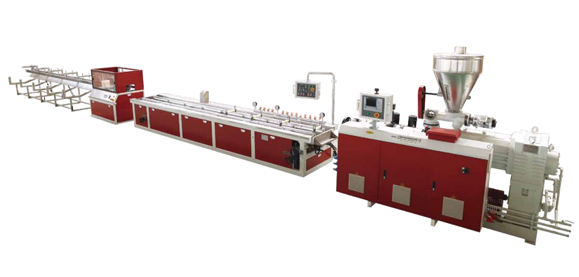

China Manufacturer for Pvc Celuka Foam Board - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Global Twin-screw Extruders Market Outlook 2018 – Clextral, Brabender, Buhler Technologies, ENTEK, Toshiba Machine, Xtrutech | Extruded Plastic Tubing

Судостроительная отрасль Крыма | Wpc Extrusion Machine

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for China Manufacturer for Pvc Celuka Foam Board - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Frankfurt , Zambia , Casablanca , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have now the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

-

New Arrival China Benchtop Plastic Extruder - ...

-

Hot sale Factory Rubber Extruder Screw - Sheet...

-

Super Purchasing for Ce Approved Quality Xps Bo...

-

Competitive Price for With Price Plastic Pellet...

-

Good User Reputation for Экструзия Полиэтилена ...

-

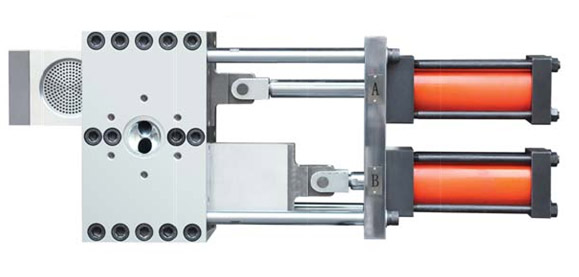

Factory directly Wenger Extruder - Hydraulic S...