China Manufacturer for Recycling Extruder - Hollow Cross Section Plate Die Series – Jwell Detail:

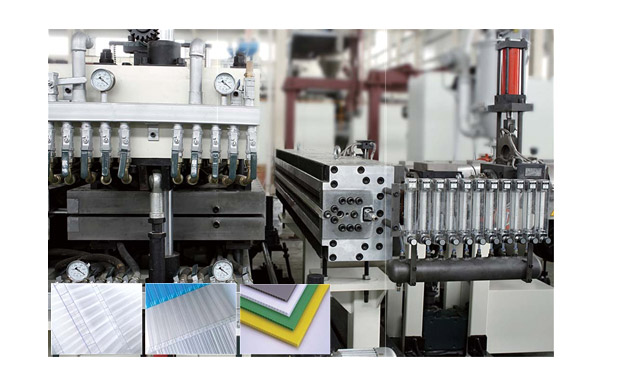

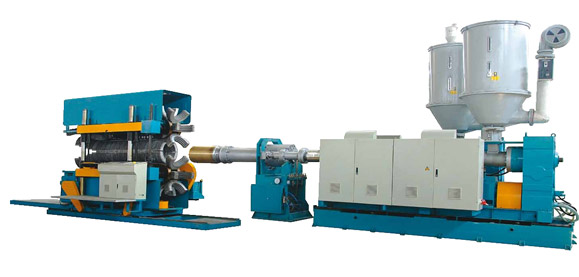

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

1С: Предприятие 8. ТОИР Управление ремонтами и обслуживанием оборудования | Производственная Линия Ppr

Extruding Machines Market Research Report Includes Business Overview, Product Specification and Top Manufactures | Screw Extruder Machine

We enjoy a very good reputation among our customers for our excellent product quality, competitive price and the best service for China Manufacturer for Recycling Extruder - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: USA , Chile , America , We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We are sincerely looking forward to establishing business relationships with friends from at home and abroad.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

-

Hot Sale for Filament Extruders - HDPE/PP/PVC ...

-

Best quality Plastic Tube Extrusion Machines - ...

-

China Gold Supplier for Lab Benchtop Small Sing...

-

Factory wholesale Plastic Drinking Straw Making...

-

New Fashion Design for Parallel Extrusion Machi...

-

Low price for Pet Sheet Extruder Line - JWZ-BM...