China OEM Extrusion Process - Film Die Series – Jwell Detail:

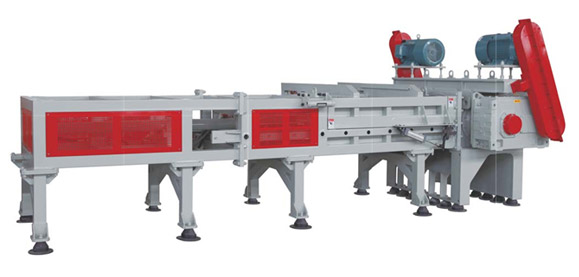

Film Die Series

Product detail pictures:

Related Product Guide:

Extrusion Cooling: It’s All About Turbulence : Plastics Technology | Wpc Extrusion Machine

Latest mechanical, hydraulic and screw extrusion presses for briquetting applications available from Briquetting Systems | Screw Extruder Machine

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for China OEM Extrusion Process - Film Die Series – Jwell, The product will supply to all over the world, such as: Lesotho , Uruguay , Russia , High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

-

Europe style for Plastic Extruder Machine Price...

-

Factory wholesale Screw Desigh Spare Part - DY...

-

Discountable price Barrel For Extruder - JWZ-0...

-

OEM Customized Ppr Pipe Extrusion Line - JWE &...

-

Best-Selling Stretch Film Machine 3 Layer Fully...

-

Renewable Design for Pp Extrusion - JWZ-BM3D-1...