factory customized Roto Moulding For Plastic Extruder Machine Manufacturer - High-speed Film Coating Die Series – Jwell Detail:

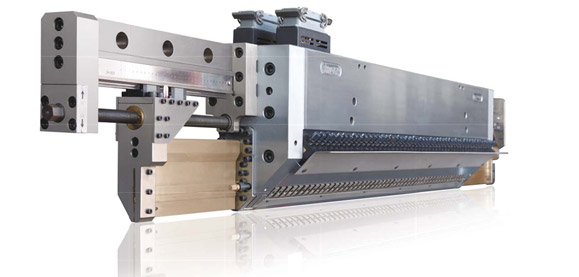

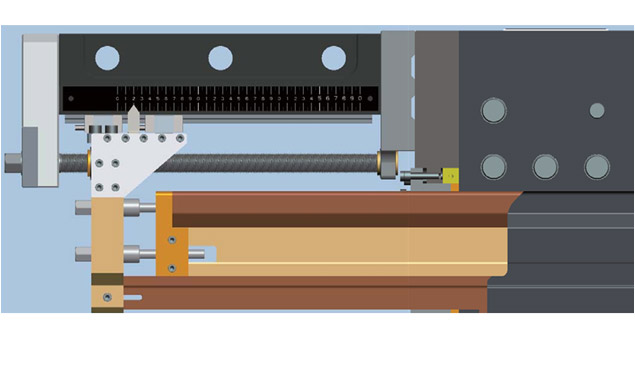

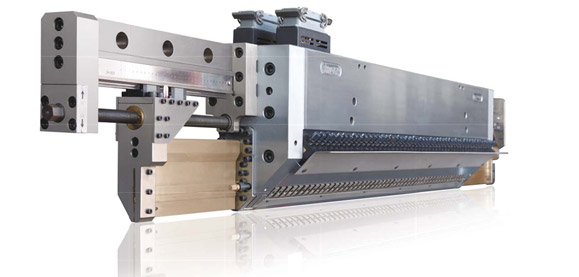

High-speed Film Coating Die Series

Product detail pictures:

Related Product Guide:

Medical Plastics Extrusion Market Report – Top 5 Players, Insights, Size, Share, Application and Forecast 2023 | Производственная Линия Ppr

Газпром в Киргизии запустил в эксплуатацию ряд важных объектов. Был там и А.Миллер // Газораспределение // Новости | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

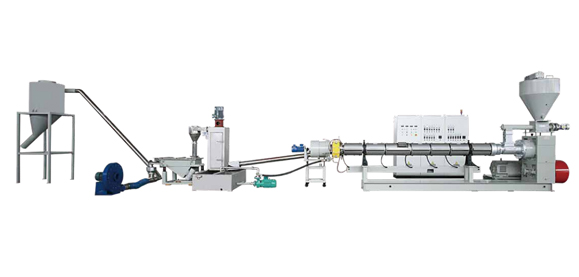

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for factory customized Roto Moulding For Plastic Extruder Machine Manufacturer - High-speed Film Coating Die Series – Jwell, The product will supply to all over the world, such as: Orlando , Madagascar , Kazakhstan , Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

-

Factory Outlets Triple Screw Extruder - JWZ-BM...

-

Big discounting Herbert Screw - JWL Series Sin...

-

OEM/ODM China Mobile Case Machine - PVC、PVG C...

-

China wholesale Pellets Extruder Machine - DYB...

-

Manufacturer of Paper Coating And Lamianting Ma...

-

Factory Cheap 2 Layers Air Bubble Film Machine ...