In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for

Sheet Extrusion

, Pipe Extrusion Line

, Plastic Extruder Parts

, We focus on to make excellent quality products to supply service for our clients to establish long-term win-win relationship.

factory low price Использовать Пластиковые Экструдер -

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

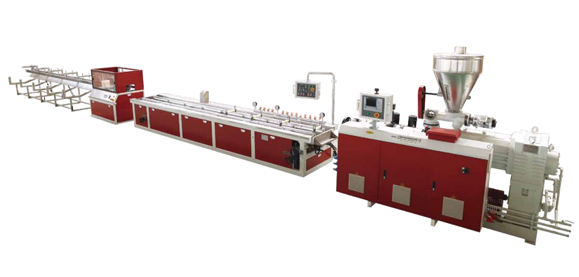

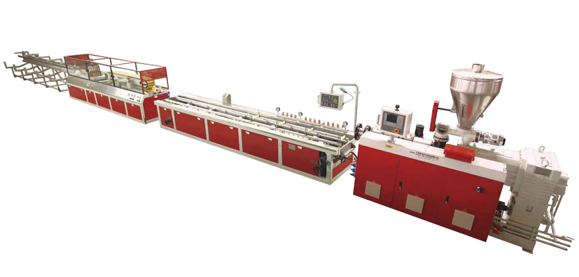

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

With perfect closed alveolate construction, XPS heat insulation plate is considered to be the best insulation material in the market. Granules from recycled EPS plate, as the main material, go through the die foaming extruder, calibrator, haul-off and cutting unit. With lower density,water absorption,thermal conductivity and vapour penetrability than of other kinds of heat insolution plates, XPS heat insulation plate features with high strength, low wight, airtightness, corrosion resistance, aging resistance and low cost. Therefore this plate can be widely used in house insulation system,in cold storage、camps、barns and civil constructions, in ground constructions of airport raceway and square, in road and railway engineering constructions,in heat insulation system of apartments,office

buildings and workshops.

XPS heat insulation plate extrusion line has two types: single screw tandem extruders type and co-rotation parallel twin screw extruder with single screw extruder.The models are: 135/150 single screw tandem extruder type and 75/150 co-rotation parallel twin screw extruder with single screw extruder.Because of high mixing efficiency, co-rotation twin screw etruder

can process material of different components.

Newly forming machine designed by Jwell, adapting CO2 as forming agent, which is for taking palce of freon and butane , features of green environment protection and low cost consumption.

Product detail pictures:

Related Product Guide:

Тихвин – Объявления, собранные для Вас с 20 июля по 1 августа | Screw Extruder Machine

Extruding Machines Market Research Report by QYResearch.us | Wpc Extrusion Machine

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for

factory low price Использовать Пластиковые Экструдер -

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Cologne

, kazakhstan

, New Orleans

, Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.