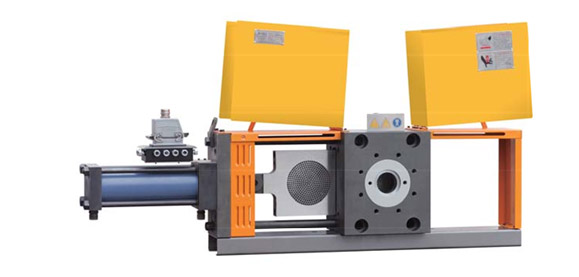

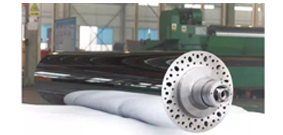

Factory selling Extrusion Moulding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Latest mechanical, hydraulic and screw extrusion presses for briquetting applications available from Briquetting Systems | Производственная Линия Ppr

Plastic Compounding Machinery Market Revenue | Market Share | Types | Applications| Opportunities | Vendors | Forecast to 2023 | Extruded Plastic Tubing

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Factory selling Extrusion Moulding Machine - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Islamabad , Estonia , Puerto Rico , We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

-

OEM Factory for Plastic Extruder Screw - Hydra...

-

OEM/ODM Supplier Wpc Door Frame Profile Plastic...

-

Cheap price Conical Twin Screw Extruder China -...

-

Manufacturer of Ppr Pipe Making Machine With Pr...

-

Hot New Products Plastic Filament Extruder Mach...

-

Factory wholesale Twin Screw Extruder Design - ...