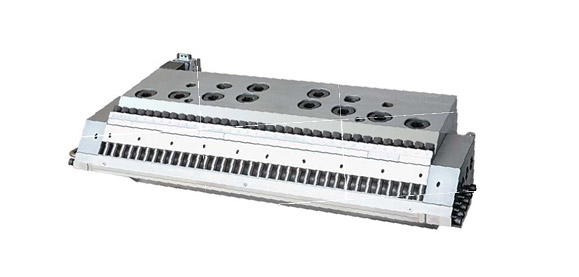

Factory selling Plastic Screw Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Pharma 11 Twin-screw Extruder from Thermo Fisher Scientific : Get Quote, RFQ, Price or Buy | Производственная Линия Ppr

Extrusion specialist talks ‘core’ competencies in medical catheter manufacturing | Производственная Линия Ppr

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value "unification, dedication, tolerance" for Factory selling Plastic Screw Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Uganda , Yemen , Chicago , We believe in quality and customer satisfaction achieved by a team of highly dedicated individuals. The team of our company with the use of cutting-edge technologies delivers impeccable quality products supremely adored and appreciated by our customers worldwide.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

-

Factory wholesale Single Screw Machine - Sheet...

-

Factory source Bimetallic Pvc Pipe Screw Cylind...

-

OEM manufacturer Экструзионная Машина Wpc - PP...

-

OEM Factory for Pvc Deco Profile Extrusion - P...

-

Hot sale Designer Mini Plastic Extruder Screw A...

-

Best Price for Kmd Parallel Twin Screw And Barr...