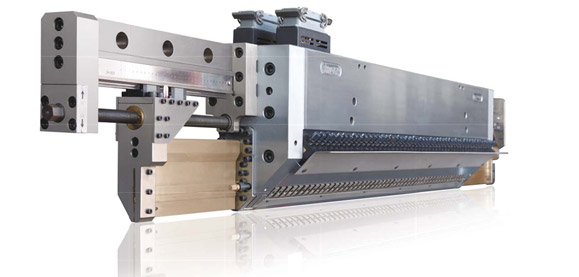

Factory supplied Plastic Channel Extrusion - Film Die Series – Jwell Detail:

Film Die Series

Product detail pictures:

Related Product Guide:

Plastic Compounding Machinery Market Revenue | Market Share | Types | Applications| Opportunities | Vendors | Forecast to 2023 | Wpc Extrusion Machine

Twin-Screw Extruder Market In Depth 2018 -2025 Size, Growth And Swot Analysis By Key Players: Matila, Toshiba Machine, Flytech, Xtrutech, Coperion | Screw Extruder Machine

The corporation upholds the philosophy of "Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth", will continue to serve outdated and new consumers from home and overseas whole-heatedly for Factory supplied Plastic Channel Extrusion - Film Die Series – Jwell, The product will supply to all over the world, such as: Grenada , Philadelphia , Muscat , Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!

-

Factory wholesale Pp Sheet Roll Extruder - Hot...

-

Excellent quality Винтовой Элемент - High-spee...

-

Free sample for Mini Plastic Extruder - Screw ...

-

Factory Cheap Экструзионная Линия По Производст...

-

Best Price on Blown Film Extrusion Plant - Con...

-

OEM/ODM China Wood Floor Making Machine - Co-r...