Factory supplied Twin Screw Extruder Working Principle - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

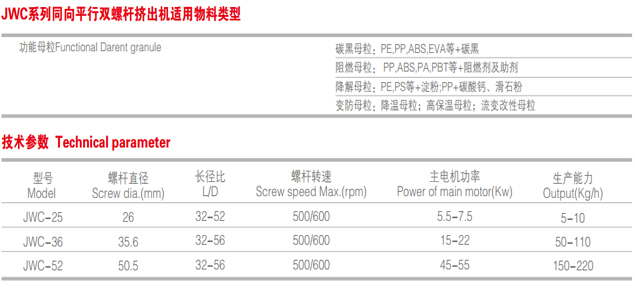

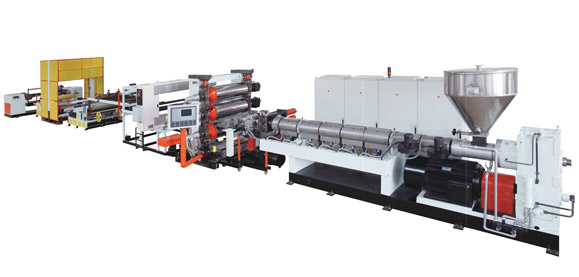

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Plastics Extrusion Market Research Report by QYResearch.us | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

В Сочи прошла церемония награждения победителей конкурса «Лидеры России» | Производственная Линия Ppr

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Factory supplied Twin Screw Extruder Working Principle - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Gambia , Cairo , Ecuador , Many goods fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

-

Factory directly supply Plastic Pipe Food Grade...

-

2017 High quality Plastic Profile With Extrusio...

-

Well-designed Rattan Furniture Machine - Singl...

-

Top Quality Upvc Profile Producer - PVB Film E...

-

Wholesale Hose Liner Extruder - Functional mas...

-

Good Quality Drip Irrigation Pipe Making Machin...