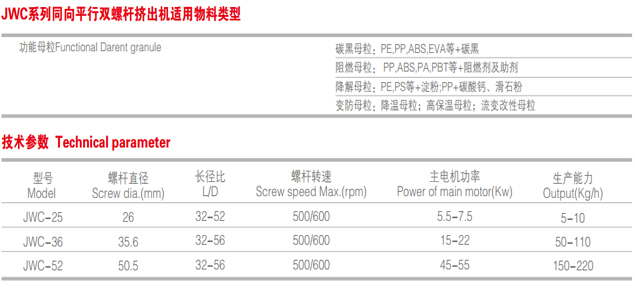

Fast delivery Twin Screw Extruder Twin Screw Extruders For Masterbatch - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

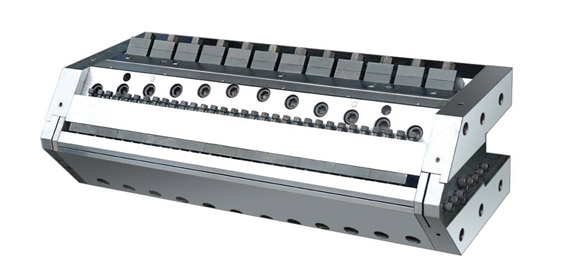

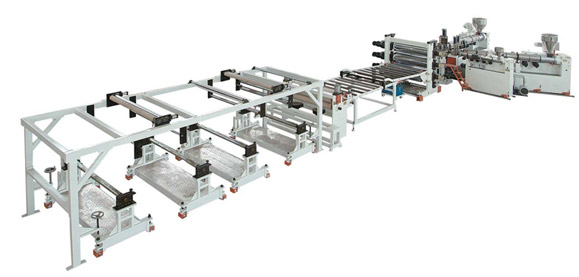

Product detail pictures:

Related Product Guide:

Plastic Extrusion Machinery Market: Scope With Inclusion And Exclusion Checklist and Forecast To 2023 | Wpc Extrusion Machine

Выключить из сети все электроприборы необходимо в ночь на воскресенье | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Fast delivery Twin Screw Extruder Twin Screw Extruders For Masterbatch - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Poland , Orlando , Spain , Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

-

Factory selling Silicone Extruder Machine - Hy...

-

New Arrival China Pe Pipe Spiral Making Machine...

-

High definition Twin Screw Extruder Price - Sh...

-

Hot-selling Wood Plastic Composite - Hydraulic...

-

Newly Arrival Acrylic Extrusion Profile - PP &...

-

Wholesale Price China Pe Pipe Extruder Single S...