High Quality H Shaped Plastic Decoration Profile - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

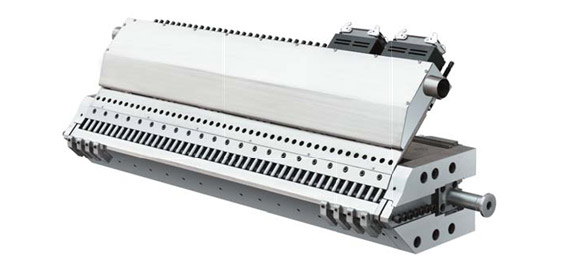

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

На Чебоксарской ГЭС проведут капремонт и замену релейной защиты блочного трансформатора // Гидроэнергетика // Новости | Wpc Extrusion Machine

KraussMaffei bags large order for more than 16 profile extruders from Adopen Plastic, Turkey | Wpc Extrusion Machine

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for High Quality H Shaped Plastic Decoration Profile - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Germany , Nepal , French , Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

-

18 Years Factory Screw Barrel For Pvc - PVC Hi...

-

Factory Price Полипропиленовая Экструзионная Ма...

-

2017 Good Quality Blow Molding Packaging Telesc...

-

Free sample for High Quality 38crmoala Bimetall...

-

Cheapest Factory Пластиковая Экструзионная Маши...

-

Discount wholesale Pp/pe/pvc Windowsill Profile...