High reputation Hdpe Pipe Extrusion Machine/line -

Hollow Cross Section Plate Die Series – Jwell

Product Detail

Product Tags

Related Video

Feedback (2)

"Based on domestic market and expand overseas business" is our development strategy for

Berstorff Extruder

, Cheap Plastic Extruder

, Pvc Core Foaming Pipe Extrusion Line

, We are willing to cooperate with business friends from at home and abroad and create a great future together.

High reputation Hdpe Pipe Extrusion Machine/line -

Hollow Cross Section Plate Die Series – Jwell Detail:

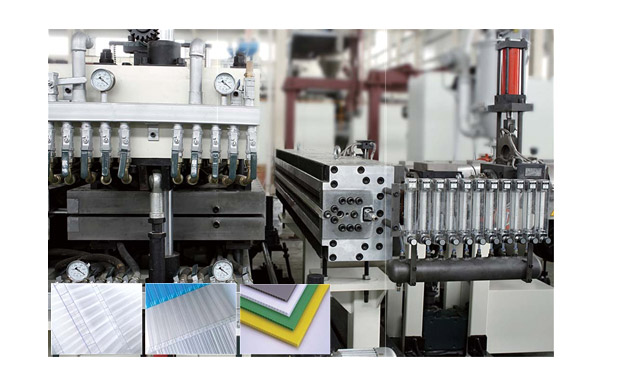

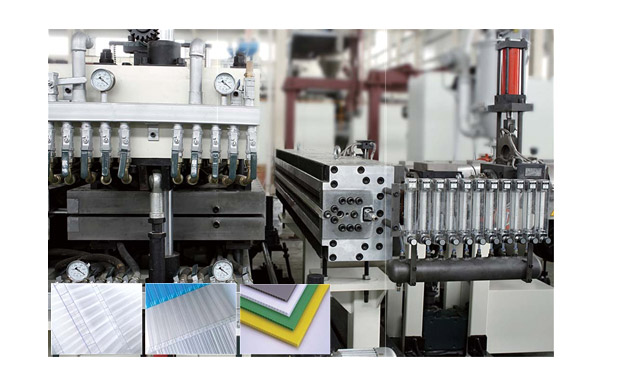

Hollow Cross Section Plate Die Series

PC hollow plate used widely in constructions and decorations.The hollow grid plate die and feedblock can make UV protection on both sides.The final production with a max width of 2100mm and have a high impact strengh, good weather resistance and UV protection.With adjustable upper and lower

mold lips, production thickness relative errors can be controlled within 3%; built-in heater features provides fast heating and superior temperature retainment.The individual air regulator can make the air volume of each section even easy to control to increase the product quality.The smoothness

of the channel reaches 0.015- 0.03um,which ensures the stagnation-proof.

Different design can meet the different requirements of products, general polycarbonate hollow plate whose thickness is between 4 to 25mm, multi-layers plate such as H-cross section, X-cross section etc, the thickness of some can reach 36mm, and the UV layer can be coated. The PP, PE hollow grid plate produced by special dies are light weighted, dampproof and have a high impact strength, which is widely used as

advertising light panel, exhibition upholster, carry box etc.The thickness-range is 2-12mm and the width is 1200-2200mm.

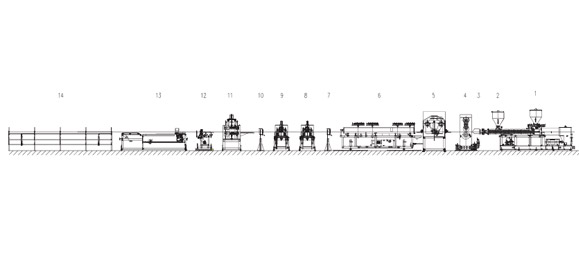

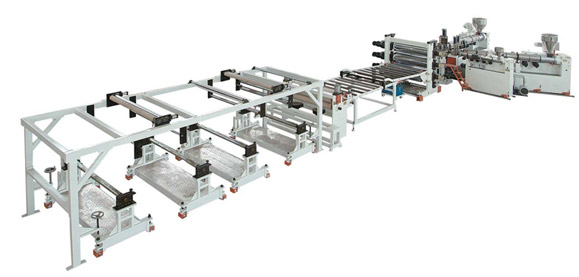

The cooling vacuume calibrator is manufactured from specially treated material assuring maximum wear resistance and deformation-free. Special temperature controlled water way and vaccum calibration design allows temperature adjustment to meet various physical property requirements for different materials.

Product detail pictures:

Related Product Guide:

Built to last | 2018-06-18 | Screw Extruder Machine

Газопровод Голубой поток за 15 лет стал мощным катализатором развития газового рынка Турции // Транспортировка и Хранение // Новости | Screw Extruder Machine

"Based on domestic market and expand overseas business" is our development strategy for

High reputation Hdpe Pipe Extrusion Machine/line -

Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: New Orleans

, Qatar

, Swiss

, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

By Jason

from Romania

- 2015.02.04 14:13

By Jason

from Romania

- 2015.02.04 14:13

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

By Diego

from Porto

- 2016.01.11 17:15

By Diego

from Porto

- 2016.01.11 17:15