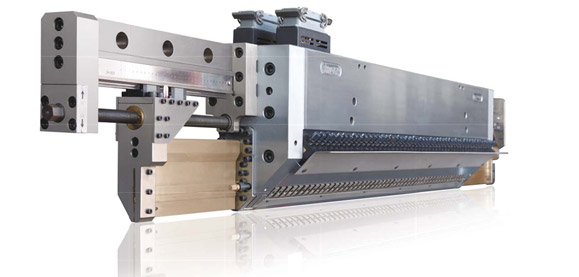

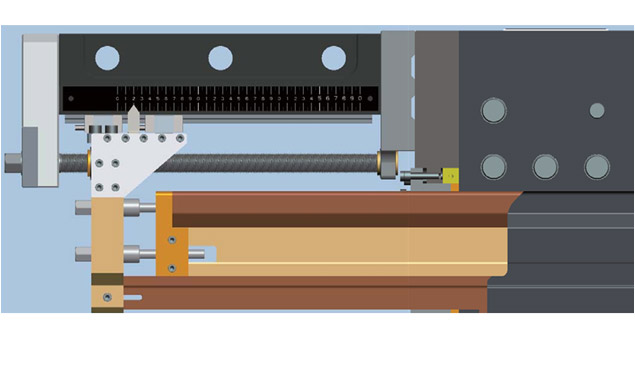

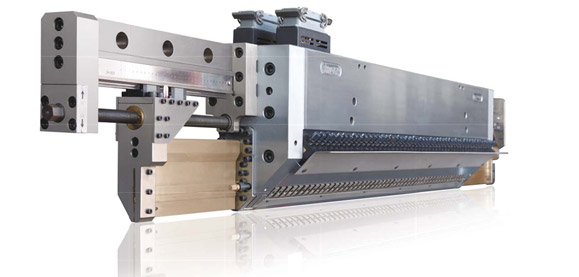

Hot sale Factory Custom Plastic Hollow Extrusions - High-speed Film Coating Die Series – Jwell Detail:

High-speed Film Coating Die Series

Product detail pictures:

Related Product Guide:

Wood Plastic Composites Market Overview, Cost Structure Analysis, Growth Opportunities and Forecast to 2021 | Производственная Линия Ppr

NeoCon 2017: This year’s show was bigger and busier than in recent years | Производственная Линия Ppr

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Hot sale Factory Custom Plastic Hollow Extrusions - High-speed Film Coating Die Series – Jwell, The product will supply to all over the world, such as: Oman , Peru , Rio de Janeiro , All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

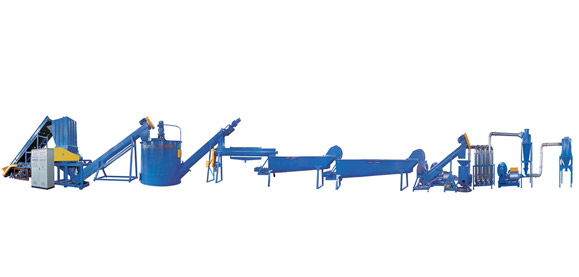

factory Outlets for Masterbatch Extruder Machin...

-

Factory wholesale Screw Desigh Spare Part - DY...

-

Hot-selling Wood Plastic Composite - Parallel ...

-

Free sample for Pp Hdpe Fishing Net Monofilamen...

-

High Performance Screw Barrel Mixhead Design Fo...

-

China Cheap price Twin Conical Screws Extruder ...