Hot Sale for Extruding Granulator - Hollow Cross Section Plate Die Series – Jwell Detail:

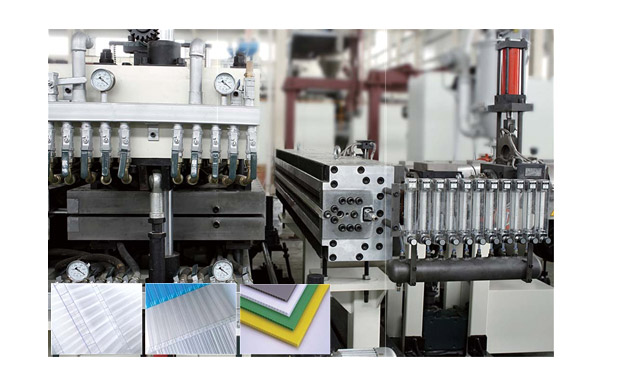

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Global Medical Plastics Extrusion Market CAGR Estimated Range 2018 To 2023 With SWOT Analysis | Extruded Plastic Tubing

Global Plastic Extrusion Machine Market Size is accounted for $xx Billion by 2025 | Производственная Линия Ppr

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Hot Sale for Extruding Granulator - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Poland , Kenya , Borussia Dortmund , As operation principle is "be market-oriented , good faith as principle, win-win as objective", holding on "customer first, quality assurance, service first" as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

-

Ordinary Discount 3d Printer Extruder - PVC Hi...

-

Professional China Twin-screw Extruder - Stret...

-

Hot New Products Plastic Extrusions Right Angle...

-

Massive Selection for Термопластичная Экструзия...

-

OEM/ODM Supplier Plastic Tube Making Machine - ...

-

OEM/ODM Factory Single Extruder Screw Barrel Wi...