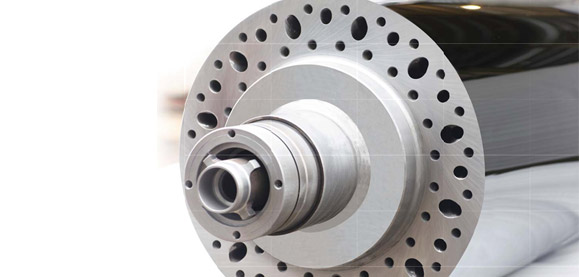

Hot sale Part Of Extrusion Machine Screw And Barrel - Film Die Series – Jwell Detail:

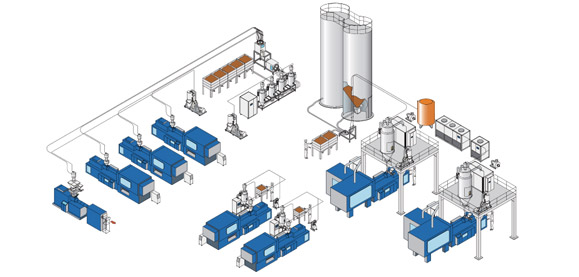

Film Die Series

Product detail pictures:

Related Product Guide:

Unique Advantages of Process Analytical Technology in Twin-Screw Granulation | Wpc Extrusion Machine

Станкосервис: АИС Диспетчер | Производственная Линия Ppr

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Hot sale Part Of Extrusion Machine Screw And Barrel - Film Die Series – Jwell, The product will supply to all over the world, such as: Dominica , Mali , Bahamas , We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

-

Factory Free sample High Quality Extrusion Scre...

-

Hot-selling Материал Шнека Экструдера - Feedin...

-

Factory wholesale Film Blown Machine - PS Foam...

-

Well-designed Pet Strap Band Extrusion Machine ...

-

High reputation Plastic Pipe Extrusion Line - ...

-

Leading Manufacturer for High Speed Single Scre...