Product Detail

Product Tags

Related Video

Feedback (2)

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for

Industrial Extruder

, Extruder Screw

, Screw Measurements

, We welcome all of the purchasers and pals to contact us for mutual added benefits. Hope to do additional business enterprise along with you.

Hot Selling for Plastic Corrugated Pipe Extruder -

Film Die Series – Jwell Detail:

Film Die Series

The die head adopts an extension V shape water-drop type flow channel,with the shunt technology and special triangle stabilize structure. To composite layer and improve the precision of the extrusion process to eliminate 'M' shape and 'W' shape flow patterns effectively. The upper die lip using push-off type manual fine-tuning + automatic fine-tuning one-piece die lip, manual adjustment range is ±1mm, automatic adjustment range ±300um; About the automatic die lip adjustment control parts ,we use currently very advanced fully closed loop control system and the automatic gauging system makes the product thickness in±2% precisely, on-line thickness gauge is automatic continuous detecting scanning frequently, can shows the very real-time accurate thickness tolerance of the products. Through computer program processing the data, feedback to special die lip adjusting bolt thermal expansion, and to realize the opening of the die lip thickness for automatic fine-tuning, fast and effective control product thickness precisely. And we have good die head scalability, according to customers’ needs , matching with different "inside blocking type width adjusting device" or "the outer blocking type width adjusting device", be better satisfied customer’s needs to more efficient production.

The die head suits for production under 5000mm,thickness between 0.06 -0.18 mm CPP, PE, EVA, PVC, PET, PVB, PA, single-layer or multilayer films.

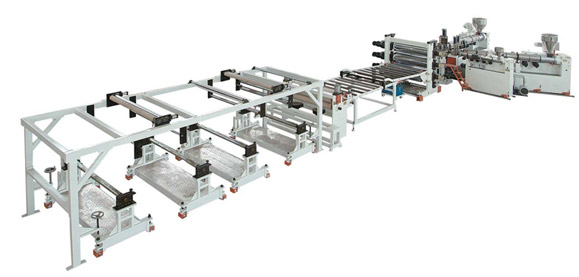

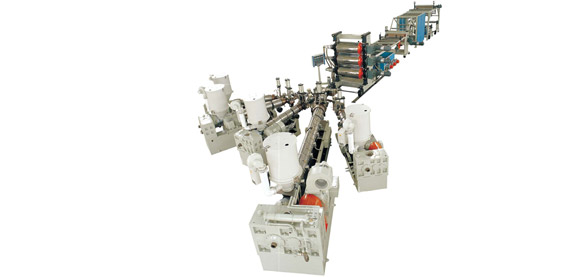

Product detail pictures:

Related Product Guide:

Увеличение мощности Топарской ГРЭС сгенерирует прибыль | Wpc Extrusion Machine

Vacuum Packaging Machines Market Industry Outlook 2018 to 2025 | Extruded Plastic Tubing

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for

Hot Selling for Plastic Corrugated Pipe Extruder -

Film Die Series – Jwell, The product will supply to all over the world, such as: Finland

, Austria

, Porto

, In the increasingly competitive market, With sincere service high quality products and well-deserved reputation, we always offer customers support on products and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

By Charlotte

from Switzerland

- 2015.12.11 11:26

By Charlotte

from Switzerland

- 2015.12.11 11:26

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!

By Eunice

from Dubai

- 2015.11.02 11:11

By Eunice

from Dubai

- 2015.11.02 11:11