Leading Manufacturer for Bubble Wrap Machine - Hollow Cross Section Plate Die Series – Jwell Detail:

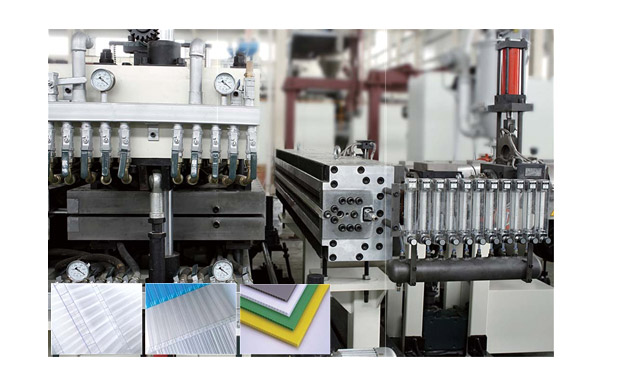

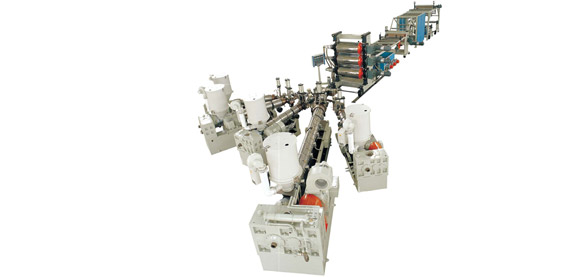

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

World of Extrusion Coming Together in September : Plastics Technology | Screw Extruder Machine

Делегация ГАЗПРОМ ТРАНСГАЗ Уфа посетила завод СТЕКЛОНИТ // В тренде // Новости | Extruded Plastic Tubing

Our pros are lessen prices,dynamic sales team,specialised QC,sturdy factories,top quality services and products for Leading Manufacturer for Bubble Wrap Machine - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Russia , Costa rica , Bahamas , we've got all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

-

PriceList for 120 Mm Single Screw Extruder - H...

-

Excellent quality Lab Conical Twin Exturder - ...

-

Factory For Twin Screw Extruder Elements - She...

-

Rapid Delivery for Plastic Strap Making Machine...

-

China Gold Supplier for Pp Pe Pipe Extruder - ...

-

Factory Price Ps Sheet Extrusion Line - JWZ-BM...