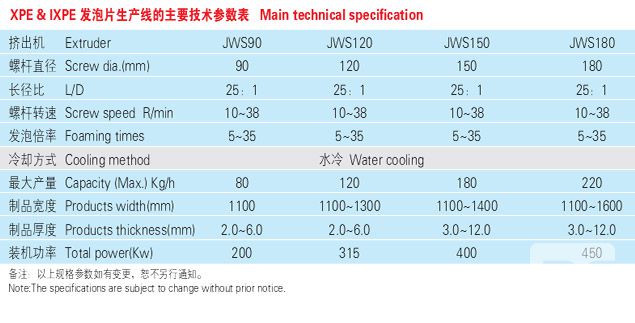

Manufactur standard Дизайн Резинового Экструдера - XPE,IXPE Foaming Coil Extrusion Line – Jwell Detail:

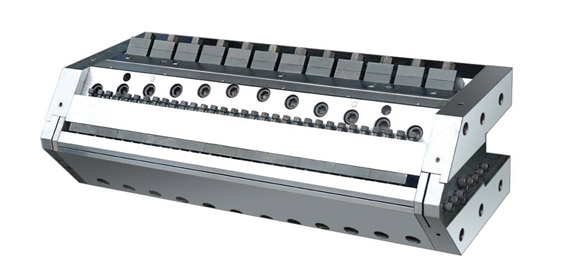

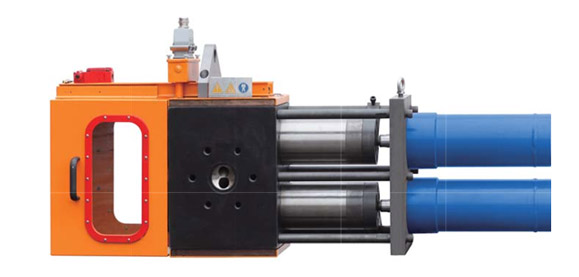

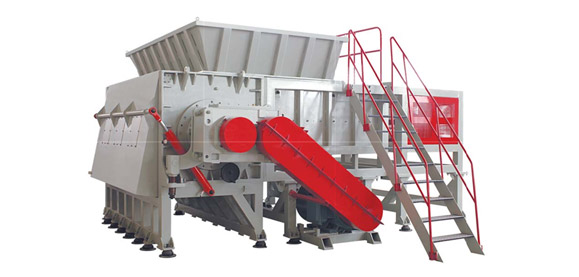

XPE,IXPE Foaming Coil Extrusion Line

Product detail pictures:

Related Product Guide:

Compounding: Quick ROI Extruder for Engineering Resins : Plastics Technology | Screw Extruder Machine

Twin-Screw Extruder Market In Depth 2018 -2025 Size, Growth And Swot Analysis By Key Players: Matila, Toshiba Machine, Flytech, Xtrutech, Coperion | Screw Extruder Machine

We enjoy an extremely good status among our prospects for our great merchandise top quality, competitive price and the ideal service for Manufactur standard Дизайн Резинового Экструдера - XPE,IXPE Foaming Coil Extrusion Line – Jwell, The product will supply to all over the world, such as: Mumbai , Jakarta , Malaysia , We are confident that we are able to provide you with opportunities and will be a valuable business partner of you. We look forward to working with you soon. Learn more about the types of products that we work with or contact us now directly with your inquiries. You are welcome to contact us anytime!

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

-

Best quality Машины Для Производства Полиэфирны...

-

Factory Free sample Pvc Lamination Machine For ...

-

Factory wholesale Cosmetic Plastic Tube Making ...

-

China Manufacturer for Sheet Machine Producer -...

-

Manufacturer of Plastic Pipe Making Machine - ...

-

Wholesale Dealers of Double Screw Polystyrene F...