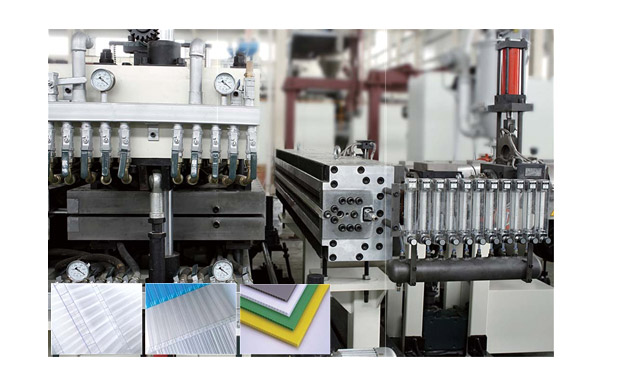

New Arrival China New Design Epe Foam Mattress Extrusion Machine - Hollow Cross Section Plate Die Series – Jwell Detail:

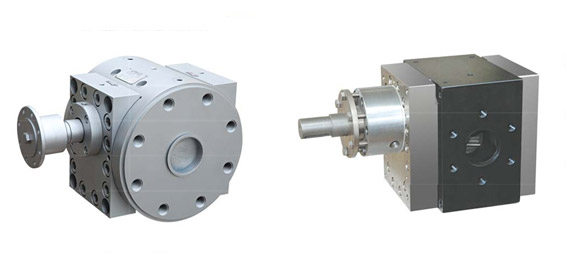

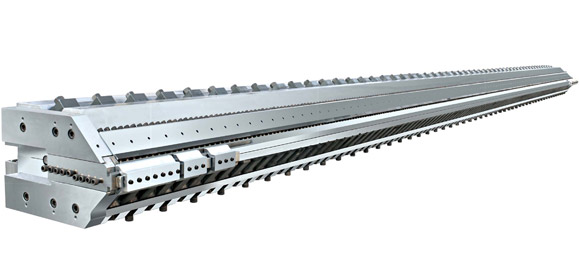

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Process Improvements Deliver Taste In Plant-Based Meat | Производственная Линия Ppr

Plastic Extrusion Machinery Market: Scope With Inclusion And Exclusion Checklist and Forecast To 2023 | Производственная Линия Ppr

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for New Arrival China New Design Epe Foam Mattress Extrusion Machine - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Holland , Eindhoven , Thailand , Our market share of our products and solutions has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future. We've been looking forward to your inquiry and order.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

-

China Cheap price Plastic Extruder Machine Scre...

-

Good User Reputation for Plastic Screw And Barr...

-

Discount Price Clear Plastic Corner Protectors ...

-

Best-Selling Plastic Recycling Machine - Water...

-

Personlized Products Extruder Machine For Sale ...

-

Wholesale Discount Double Piston Screen Changer...