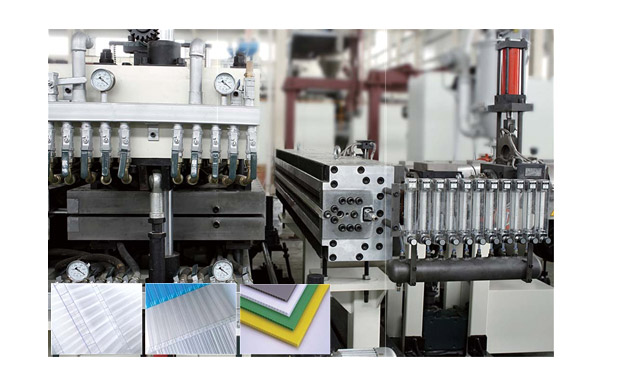

New Delivery for Пластиковые Экструдеры Ltd - Hollow Cross Section Plate Die Series – Jwell Detail:

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Hillenbrand (NYSE:HI) and Kid Brands (KIDBQ) Financial Review | Screw Extruder Machine

Pharma 11 Twin-screw Extruder from Thermo Fisher Scientific : Get Quote, RFQ, Price or Buy | Производственная Линия Ppr

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for New Delivery for Пластиковые Экструдеры Ltd - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Namibia , Kuwait , Mexico , Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

A good manufacturers, we have cooperated twice, good quality and good service attitude.

-

Manufacturer for Mini Plastic Extruder Machine ...

-

China New Product Lab Extruder Machine Sale - ...

-

Chinese Professional Hand Plastic Extruding Wel...

-

Excellent quality Polycarbonate Extruded Tube -...

-

New Fashion Design for Multy-layers Extruder - ...

-

100% Original Plastic Extruder Manufacturer - ...