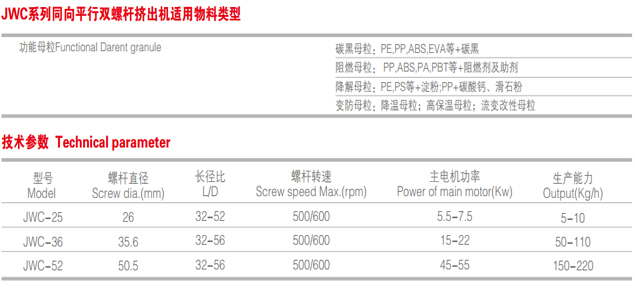

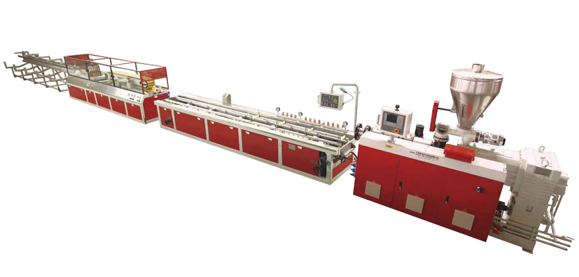

OEM China Lab Single Screw Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Когда у Белорусских цементных заводов откроется второе дыхание | Производственная Линия Ppr

Why PEEK is so hard to extrude | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for OEM China Lab Single Screw Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Zimbabwe , Kuala Lumpur , Oslo , As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

-

Original Factory Extruder Bolt - JWZ-BM160/230...

-

Personlized Products Pvc Ceiling Panel Extrusio...

-

Low MOQ for Screw Element - DYPS Series Strong...

-

China New Product Twin Screw Extruder For Plast...

-

High definition Medical Tube Plastic Extrusion ...

-

Factory supplied Desktop Plastic Extruder - JW...