OEM China Water Pipe Twin Screw Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

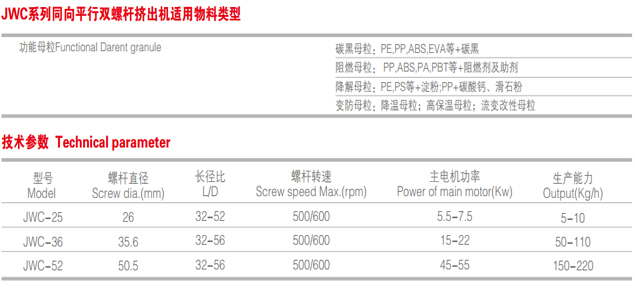

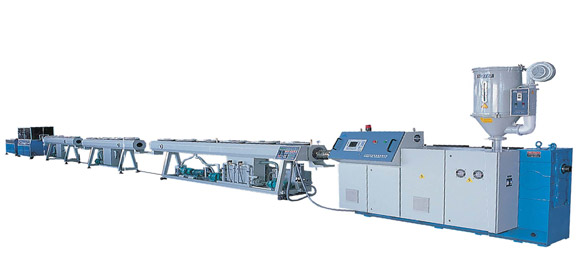

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Plastic Extrusion Machine Market to Register Steady Expansion During 2017-2027 | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

American Securities Acquires CPM | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for OEM China Water Pipe Twin Screw Extruder - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Bulgaria , Iran , Doha , Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

-

factory low price Drinking Straw Extruding Mach...

-

Good User Reputation for Auto Pp Sheet Extrusio...

-

Manufacturing Companies for Corrugated Pipe Mak...

-

factory Outlets for Пластиковая Трубчатая Машин...

-

factory Outlets for Screw Design For Plastic Ex...

-

OEM Supply Double Wall Corrugated Pipe Producti...