OEM Customized Plastic Bag Extruder Machine - Hollow Cross Section Plate Die Series – Jwell Detail:

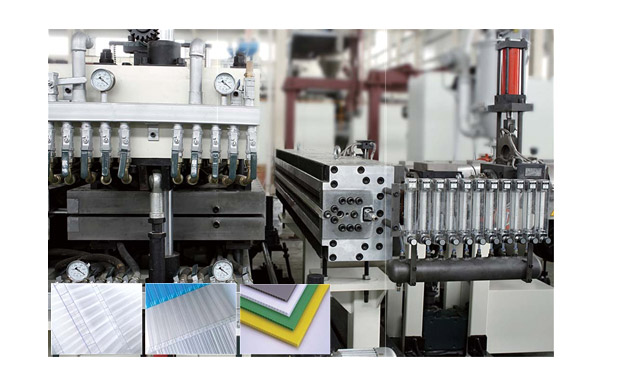

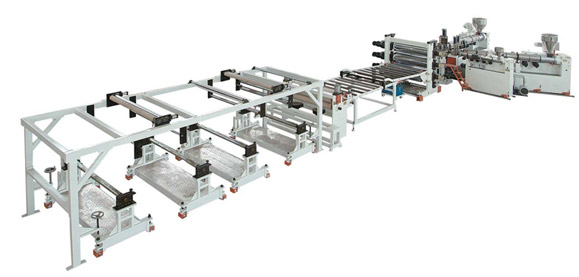

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Twin Screw Extruders Market 2023 by Opportunities, Restraints Product, Key Developments, Overview and Forecast | Screw Extruder Machine

Alliance Rubber to add silicone extrusion | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Our products are greatly acknowledged and reliable by users and may fulfill repeatedly shifting financial and social wants for OEM Customized Plastic Bag Extruder Machine - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Belgium , United States , Pakistan , In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

Hot Selling for Pc Sheet Extrusion Line - High...

-

OEM Manufacturer Pp Pipe Extruder Single Screw ...

-

Factory Cheap Hot Полимерное Экструзионное Обор...

-

Factory supplied Двухшнековая Экструдерная Обра...

-

Personlized Products Plastic Extruder For Pp - ...

-

Wholesale Dealers of Pvc Single Wall Corrugated...