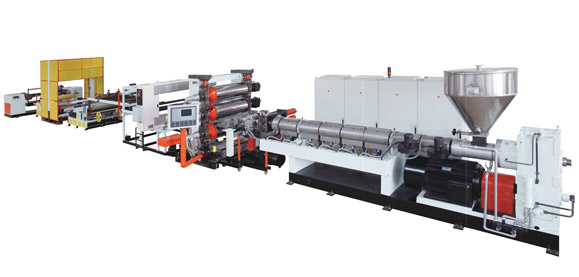

OEM Factory for Waste Recycling Plant - Film Die Series – Jwell Detail:

Film Die Series

Product detail pictures:

Related Product Guide:

How microextrusion medical tubing is leading to new procedures | Wpc Extrusion Machine

Global Twin-Screw Extruder Market 2019 Analysis By Manufacturers: The Theysohn Group, MATILA, Toshiba Machine, Coperion | Extruded Plastic Tubing

Our products are greatly acknowledged and reliable by users and may fulfill repeatedly shifting financial and social wants for OEM Factory for Waste Recycling Plant - Film Die Series – Jwell, The product will supply to all over the world, such as: Lesotho , Tunisia , Swansea , We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

-

Special Design for Single-screw Extruder Machin...

-

Ordinary Discount Трубная Линия Экструзии Pe - ...

-

100% Original Extruder Bimetallic Screw Barrel ...

-

New Delivery for Cheap Fiberglass Profiles For ...

-

factory Outlets for Пластиковая Трубчатая Машин...

-

Well-designed Pp String Wound Filter Cartridge ...