OEM Manufacturer Конструкция Винт-Смесителя - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

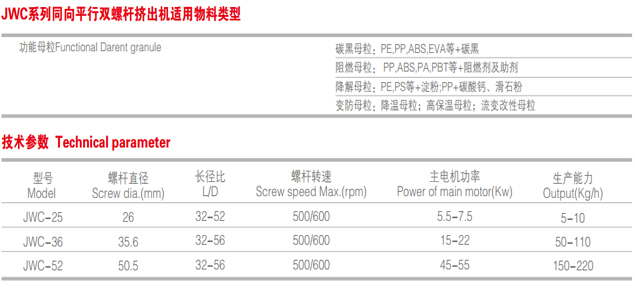

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

Product detail pictures:

Related Product Guide:

Unique Advantages of Process Analytical Technology in Twin-Screw Granulation | Extruded Plastic Tubing

American Securities Acquires CPM | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

With this motto in mind, we've come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for OEM Manufacturer Конструкция Винт-Смесителя - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Burundi , Sri Lanka , Netherlands , With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

Best Price for Pet Strapping Line Machine - Pl...

-

New Fashion Design for Wenger Extruder Machine ...

-

Manufacturing Companies for Corrugated Pipe Mak...

-

Hot Sale for Extrusion Screw Compression Ratio ...

-

OEM/ODM Supplier Roof Forming Machine - PP Sup...

-

Hot sale Compounding Extruder - Sheet Die Seri...