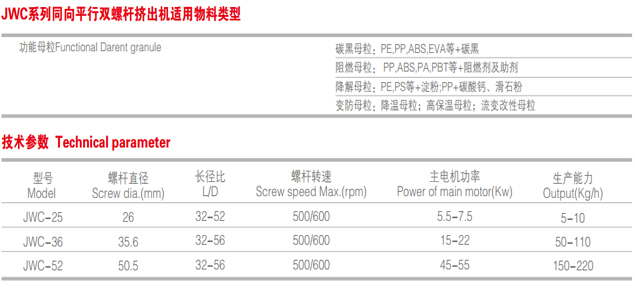

OEM/ODM Supplier Twin Screw Extruder Parts - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

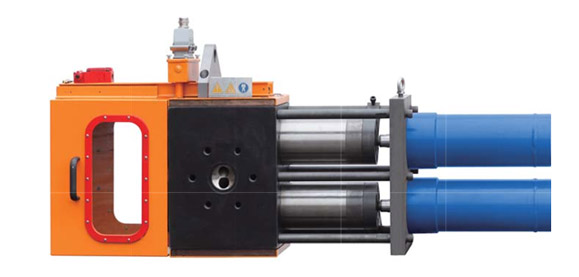

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

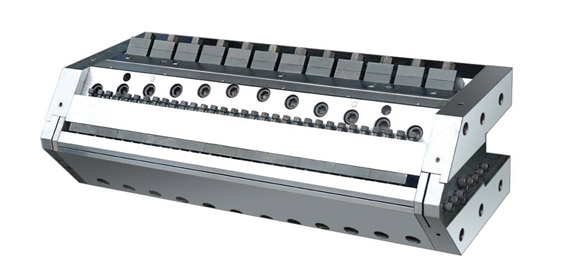

Product detail pictures:

Related Product Guide:

На Чебоксарской ГЭС проведут капремонт и замену релейной защиты блочного трансформатора // Гидроэнергетика // Новости | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

Global Twin-screw Extruders Market 2018 Sales Revenue Analysis, Major Manufacturers Performance, Industry Share and Forecast 2025 | Производственная Линия Ppr

Our organization insists all along the quality policy of "product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as the consistent purpose of "reputation 1st, purchaser first" for OEM/ODM Supplier Twin Screw Extruder Parts - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Brisbane , Turkey , Melbourne , We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

A good manufacturers, we have cooperated twice, good quality and good service attitude.

-

Manufactur standard Decorative Wall Moulding - ...

-

Best Price for Pvc Pellet Machine - RTP Compos...

-

Factory source Pvc Foam Board Manufacturing Mac...

-

Low MOQ for Upvc Window Profile Producer - Hot...

-

Renewable Design for Ic Packaging Tube Making M...

-

High Quality Single Screw Extruder Suppliers - ...