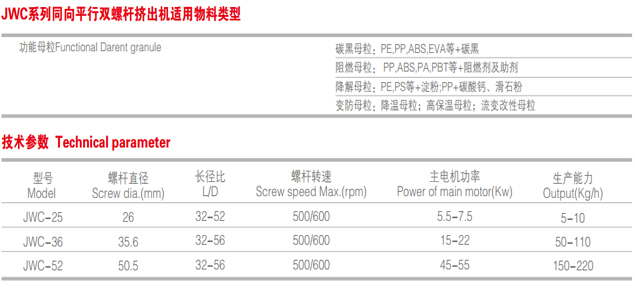

One of Hottest for Plastic Extruding Machine - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell Detail:

JWE Co-rotation Parallel Twin-screw Pelletizing Machine

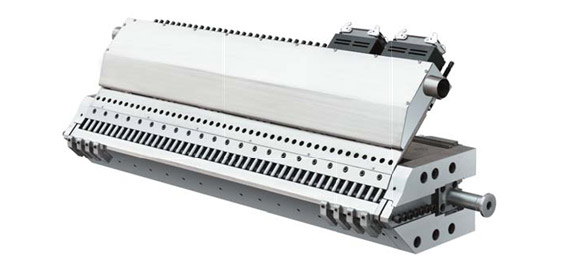

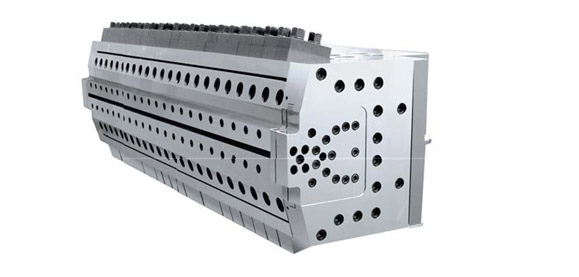

Product detail pictures:

Related Product Guide:

Патологические детские привычки: как с ними бороться? | Screw Extruder Machine

Global Plastics Extrusion Market CAGR 2018 – Swot Analysis, Porters Five Forces Analysis, Forecast Till 2023 | Screw Extruder Machine

With this motto in mind, we've come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for One of Hottest for Plastic Extruding Machine - JWE Co-rotation Parallel Twin-screw Pelletizing Machine – Jwell, The product will supply to all over the world, such as: Barbados , Malta , Toronto , Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.

-

PriceList for Линия Экструзии Листов Из Пвх - ...

-

Discountable price Double Screw Extruder Design...

-

Wholesale Price Tube Extruder Machine - Sheet ...

-

Factory source Plastic Granules Making/cutting ...

-

Personlized Products Подержанное Экструзионное ...

-

Factory Price Extrude Plastic Profiles - Conic...