PE Breathable Film Production Line

Short Description:

product description our certificates FAQ request a quote Menu product description our certificates FAQ request a quote Since the fight against the pneumonia epidemic caused by the novel coronavirus, as companies gradually resume work, the shortage of medical protective products has eased, but there is still a gap. In particular, as a “teater” protective suit for medical staff, it is generally replaced every 4 hours, which is in great demand. Jwell provides PE Br...

Product Detail

Product Tags

Since the fight against the pneumonia epidemic caused by the novel coronavirus, as companies gradually resume work, the shortage of medical protective products has eased, but there is still a gap. In particular, as a “teater” protective suit for medical staff, it is generally replaced every 4 hours, which is in great demand. Jwell provides PE Breathable Film Production Line for manufacturers

Disposable medical protective clothing materials need to meet the requirements of “three resistance and one resistance” (that is, water repellent, blood repellent, alcohol repellent, and antistatic) requirements of micro-nano grade materials. This composite material can be combined with different materials, such as polyethylene/polypropylene spun-bonded nonwoven fabric, combined with breathable microporous film or other nonwoven fabric, or spun lace nonwoven fabric combined with breathable microporous film, or Wooden paddle composite spun lace nonwoven fabric. In addition, some membranes made of PTFE can be used for high-end protective clothing fabrics. In the composite of these materials, the breathable microporous film is particularly important.

The so-called breathable film is a kind of functional inorganic product that is uniformly mixed into the polyolefin raw material, so that the product has pores due to high stretching during the film formation process, so as to have the function of breathability and moisture transmission; the function of the breathable film In short: Waterproof and breathable (moisture), take the most commonly used PE as a carrier as an example.

- The principle of breathability

The principle is very simple: inorganic matter + stretching = micropores. In fact, the operation is very particular. Only micropores with proper size and uniform distribution are effective. As shown in Figure 1:

As shown in Figures 2 and 3 below, insufficient stretching and too small pore size, insufficient stretching and no pore size, poor stretching, and insufficiently sized micropores can only be waste products.

- Basic film-forming principle of breathable film

The film-forming principle of the breathable film: PE+CaCO3 (masterbatch) — film formation — stretching — breathable film

PE breathable film is blended with LDPE/LLDPE polyethylene resin carrier by adding about 50% of special calcium carbonate, and then oriented and stretched to a certain ratio after being extruded into a film. Since polyethylene resin is a thermoplastic plastic material, it can be stretched and crystallized under certain conditions. During stretching, the interface between the polymer and the calcium carbonate particles will be peeled off, and the interconnected serpentine pores are formed around the calcium carbonate particles. Or channels, it is these pores and channels that give the film a breathable (wet) function, thereby communicating the environment on both sides of the film.

- The mechanism of action of a breathable membrane

When the water vapor concentration on one side of the film is greater than the environment on the other side of the film, a humidity gradient pressure difference is formed. This provides the basic conditions for gas (vapor) convection. Due to the formation of convection, the humidity environment on both sides of the film tends to be relatively balanced.

The breathable membrane is used as a water-proof membrane, which has a barrier effect on liquids. Because of the many passages in the membrane, the tortuous channel formed by it has a large “L/D” value, which can be understood as a capillary. Therefore, under the same liquid (such as water) and the same pressure, as long as the height of the liquid column of the capillary is less than the length of the capillary, it can be ensured that the liquid will not leak out.

The production line use PE air-permeable plastic granules as raw material, and uses an extrusion casting method to melt-extrude the PE-modified air-permeable plastic granules containing inorganic filler through a flat die, and the roller is stretched at a high rate to produce a sub-nanometer micro Porous membrane.

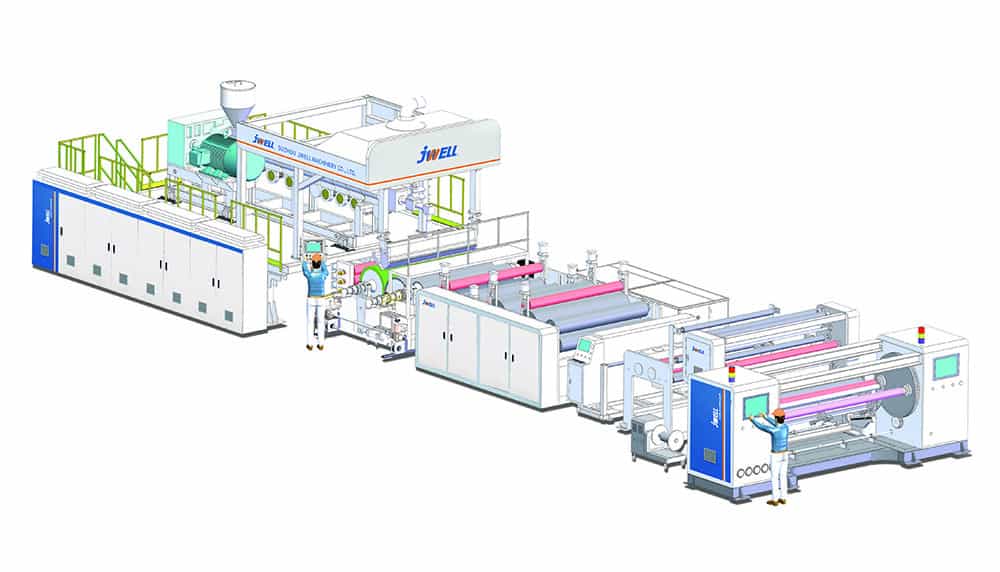

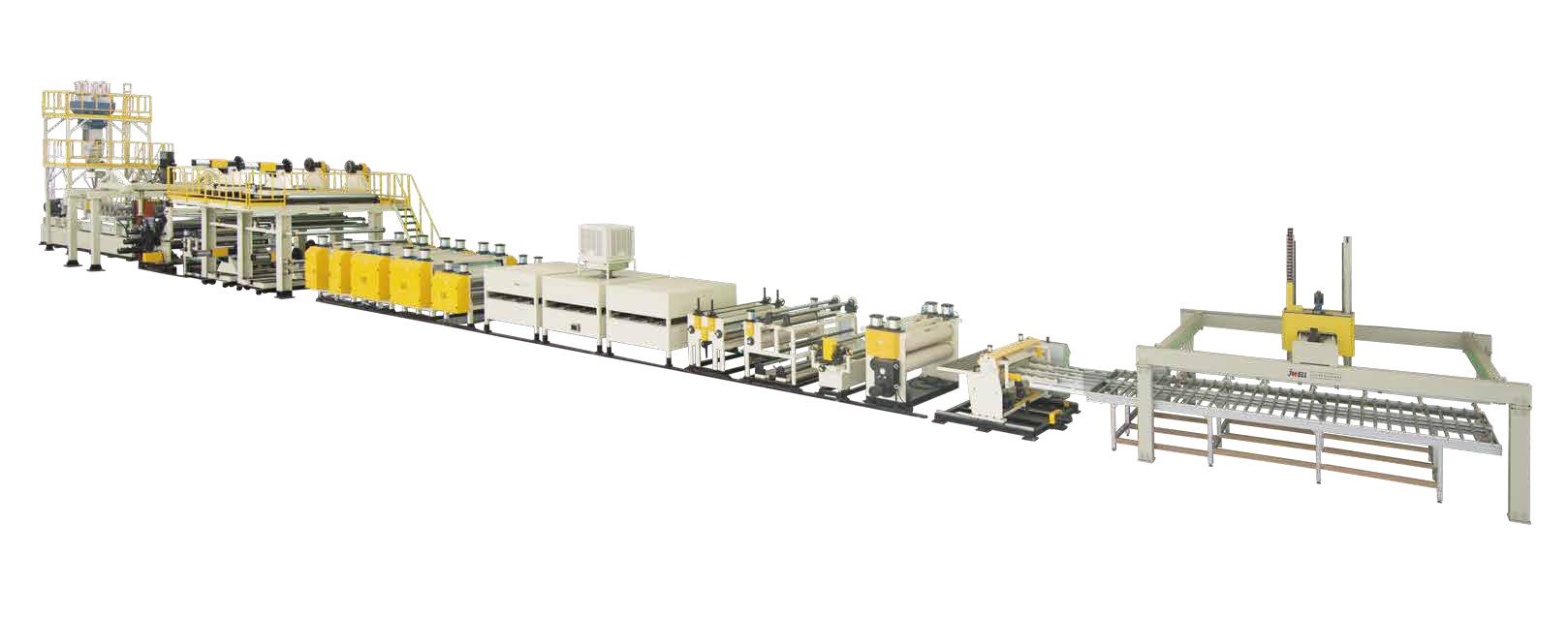

PE Breathable Film Production Line

Model: JWS130-1800

General:

1.Utility source:

Electric Power Supply: All Cabinets(including main power supply and control) and all internal cables will be supplied by the seller, buyer’s responsibility is for external cables and cable frame to main panel/input power position of sheet extrusion machine)

Mains input 3×380V (Volt)

Fluctuation max ≦+/-15%

Frequency 50HZ

Fluctuation max +/-1.5HZ

Cooling water supply: water used on machinery in closed or open-loop circuits must follow the general requirement: clean filtered and free of sediments.

Supply temperature 30℃

Supply pressure 0.2~0.3Mpa

Pressure variation +/-0.5bar

Return pressure average 1.5bar

consumption capacity 20-30m3/h

Compressed air supply: clean, free of oil, dust, and water

supply pressure at the point of use 0.5~0.7Mpa

Pressure variation +/-1%

Consumption capacity 0.9 m3/h

2.Technica Data:

Extruder (JWS130/36) PE+CaCo3 pellet

Design output 500-600 Kg/h

Finished product width 1800 mm

Product thickness 0.015-0.05 mm

Deviation ±5%%

Design maximum linear speed 200 m/min

Production speed 120-150 m/min

Total installed power 700 KW

Total length of production line 24 meter

Maximum production line width 8 meter

The total maximum height of the production line 5 meter

3.Equipment list

- Feeder system 1set

- JWS130/36Extruder 1set

- Screen changer 1set

- Gear pump 1set

- T-die 1set

- Castingroller calender 1set

- cooling forming system1set

- Thickness gauge system1set

- Horizontal stretching machine 1set

- Corona treatment system 1set

- Haul-off unit 1set

- Defect detection system 1set

- Take/off and Film trimming system 1set

- Disc type double station winder 1set

- Trimming waste recycling system 1set

- Electrical control system 1set

- Spare parts 1set

Details

1.Feeder system

Vacuum negative pressure suction machine Max capacity 500-600kg/h

Suction motor power 5.5kw

The suction pipe adopts stainless steel fixed pipeline, and the feeding site is tidy

2.Extruder

Specification model JWS130/36 TQM

Design capacity Max: 500-600kg/h

Screw and barrel BM type screw and barrel, manufactured by the introduction of German technology, made by Jwell, Jinhailuo brand, founded in the 1978 year

Screw diameter Φ130mm

Screw length to diameter ratio 36:1

Main motor power AC 200KW

Main motor brand Siemens Beide or Brazil WEG AC motor

Gearbox adopts integral box body, hard tooth surface, high torque, vertical structure

Gearbox brand domestic high-quality gearbox brand of Jiangyin Gearbox General Factory

Gearbox cooling External heat exchanger is provided with water to cool the gear oil, and the hard pipe is connected to the waterway

Cooling of the feed section of the barrel, overflow water jacket cooling, external water cooling for cooling, hard pipe connection to the waterway

Barrel heating power and temperature control 7 zones X 8KW, ceramic heating;

Barrel cooling power and temperature control 7 zones X 0.55KW forced air cooling

Extruder base The operating steel platform is welded by square tube steel, which is stable and firm. Equipped with safety guardrail and escalator;

3.Screen changer

Specification model 150 single-board single station

Screen changing form: hydraulic automatic screen changing

Hydraulic station 3K hydraulic station with accumulator and hydraulic oil tank

Pressure monitoring feedback 1 set of domestic-made Xinda brand pressure sensor in front of the network

4.Gear pump

Specification model 250CC

Metering pump origin brand Domestic high-quality brand

Transmission system brand American Rexnord reduction transmission system, FALK brand

Transmission motor power 18.5KW

Melt metering pump constant temperature Matching a 9KW mold temperature machine to accurately control the overall temperature of the melt pump

Pressure monitoring feedback The front of the pump is equipped with a set of imported Geffron brand pressure sensors; the rear of the pump is equipped with a domestic-made Xinda brand pressure sensor.

5.T-die

Pressure JWELL brand 2400mm T-die

Material 2738 alloy steel

Design Cloth hunger type

Runner Mirror plated hard chrome polished

Mold mounting frame With a quick disassembly device, easy to clean the mold

6.Casting cooling forming system

Matting roller 1pcs

The main drive of the casting machine 11KW variable frequency geared motor

Matte casting roll 1 Φ740mmX2800mm spiral runner roller, advanced internal runner design scheme makes the roller two

End temperature error is extremely small; the surface of the roller is electroplated with hard chromium and then matted; the roller is dynamically balanced with high precision

Calibration; one rotary joint on the left and right is matched;

Liquid silicone roller 1 Φ600mmX2800mm spiral flow channel liquid silicone roller, advanced internal flow channel design scheme makes

The temperature error at both ends of the roller is extremely small; the surface of the roller is coated with liquid silica gel; the roller undergoes high-precision movement

Balance check; one rotary joint on the left and right is matched;

Cooling pressure roller 2 Φ200mmX2800mm spiral runner rollers, advanced internal runner design scheme makes the rollers two

The end temperature error is extremely small; the surface of the roller is electroplated with hard chromium and polished; the roller is flattened with high precision

Scale calibration; supporting one rotary joint on the left and right;

Cooling roller opening and closing Air cylinder opening and closing

Silicone roller pressing system Double hydraulic cylinder opening and closing

Hydraulic station 3K hydraulic station with accumulator and hydraulic oil tank

Guide roller 1 Φ120X2800mm aluminum guide roller, the surface of the roller is polished and hardened; the roller is high-precision

Degree of dynamic balance check;

Centralized water supply and drainage Two sets of stainless steel transition water tanks, centralized water supply and centralized discharge of cooling water for casting machine, and drag chain movement;

Adjusting the center height of the casting machine, integral linkage lifting, geared motor drive, and manual dual-use

Casting machine translation device 1.1KW geared motor drive and manual dual-purpose overall translation, moving range 3.8 meters

7.After cooling setting system

Cooling setting machine drive 7.5KW variable frequency geared motor

Rear cooling roller 2 Φ350X2800mm spiral runner rollers, advanced internal runner design scheme makes both ends of the roller

The temperature error is extremely small; the surface of the roller is electroplated with hard chromium and then polished and polished; the roller is leveled with high precision

Scale calibration; supporting one rotary joint on the left and right;

Guide roller 1 Φ120X2800mm aluminum guide roller, the surface of the roller is polished and hardened; the roller is high-precision

Degree of dynamic balance check;

8.X-ray probe thickness gauge

Brand origin: domestic high-quality brand

Detection width 0-2700mm

Detection range 0.01-0.1mm

Scanning speed 10-100mm/s

Repeat detection accuracy 1um

Scanning accuracy ±1um

Scanning positioning accuracy 0.5mm

Synchronization accuracy 1mm

Working power 2.5KW

Control operating system 21-inch LED color display, keyboard, and mouse man-machine interface control system; also equipped with a front secondary display, square

Adjust the mold opening operation

Guide roller 2 Φ120X2800mm aluminum guide roller, the surface of the roller is polished and hardened; the roller is high-precision

Dynamic balance check

9.Horizontal stretching machine

9.1 Preheating system

3 sets of precise oil temperature control preheating roller system;

3 sets of 5.5KW variable frequency motor deceleration system drive;

supporting independent precise temperature control mold temperature machine.

Preheating roller 3 Φ450X2800mm spiral runner rollers, advanced internal runner design scheme makes the temperature error at both ends of the roller extremely small;

the surface of the roller is electroplated with hard chromium and then polished and polished;

the roller undergoes high-precision dynamic balance verification;

Supporting a rotary joint on the left and right;

3 compression rubber rollers Φ240X2800mm compression rubber roller, the surface of the roller is covered with EPDM wear-resistant rubber;

the roller has undergone high-precision dynamic balance verification;

dual-cylinder pneumatic opening and closing Squeeze;

9.2 Stretching system

4 sets of precise oil temperature-controlled stretch roller system;

4 sets of 7.5KW variable frequency motor deceleration system drive;

supporting precise temperature control mold temperature machine;

Stretching rollers 4 Φ270X2800mm spiral runner rollers, advanced internal runner design scheme makes both ends of the roller, The temperature error is extremely small;

the surface of the roller is electroplated with hard chromium and then polished and polished;

the roller has undergone high-precision dynamic balance verification;

it is equipped with a rotary joint on each side;

Compression rubber roller 4 Φ240X2800mm compression rubber roller, the surface of the roller is covered with EPDM wear-resistant rubber treatment;

the roller has undergone high-precision dynamic balance verification;

dual-cylinder pneumatic opening and closing compression;

4 back pressure rollers Φ200X2800mm steel back pressure roller, the surface of the roller is electroplated with hard chromium and then polished and polished;

the roller undergoes high-precision dynamic balance verification;

double cylinder pneumatic opening and closing compression;

9.3 Heat setting system

3 sets of heat setting roller system with precise oil temperature control, 3 sets of 5.5KW variable frequency motor deceleration system drive;

Supporting independent and precise temperature control mold temperature machine

Heat setting rollers 3 Φ450X2800mm spiral runner rollers, advanced internal runner design scheme makes the temperature error at both ends of the roller extremely small;

the surface of the roller is electroplated with hard chromium and then polished and polished;

the roller undergoes high-precision dynamic balance verification;

One rotary joint on the left and right;

Compression rubber rollers 3 Φ240X2800mm compression rubber surface rollers, the surface of the rollers are covered with EPDM wear-resistant rubber treatment;

the rollers have undergone high-precision dynamic balance verification;

dual-cylinder pneumatic opening and closing compression;

9.4 Cooling shaping system

4 sets of precise oil temperature control cooling shaping roller system, 4 sets of 5.5KW frequency conversion motor deceleration system drive;

The valve can control the flow rate so that the roller can quickly cool the product and have a good effect;

Cooling roller 4 Φ450X2800mm spiral runner rollers, advanced internal runner design scheme makes the temperature error at both ends of the roller extremely small;

the surface of the roller is electroplated with hard chromium and then polished and polished;

the roller undergoes high-precision dynamic balance verification;

One rotary joint on the left and right;

Compression rubber rollers 4 Φ240X2800mm compression rubber surface rollers, the surface of the rollers are covered with EPDM wear-resistant rubber treatment;

the rollers have undergone high-precision dynamic balance verification;

dual-cylinder pneumatic opening and closing compression;

Extension guide rollers 2 Φ120X2800mm aluminum guide rollers, the surface of the roller is polished and hardened;

with an extended exhaust groove;

the roller has undergone high-precision dynamic balance verification;

Guide roller 1 Φ120X2800mm aluminum guide roller, the surface of the roller is polished and hardened;

the roller undergoes high-precision dynamic balance verification;

Features of the horizontal stretching unit The frame adopts thickened high-strength steel plates as the wall panels on both sides, and the overall design is stable and firm with little vibration;

it is equipped with an escalator and a bridge operation inspection platform with safety guardrails;

it is equipped with a chain automatic film-piercing device for operation Convenient;

the transmission between the rollers adopts a tooth surface quenched helical gear transmission system, which has high transmission efficiency and low noise;

the unit is equipped with 8 24KW oil temperature controllers to ensure the accurate and controllable temperature of the rollers of the unit system.

10.Corona treatment system

Brand Place of Origin Domestic High-Quality Guangxin Brand

Effective corona width range 0-2500mm, double-sided corona, single-sided and double-sided switchable;

Working power 12KW (6X2) corona treatment machine;

Corona electrode 2 sets of aluminum alloy electrode, double cylinder pneumatic opening and closing;

Corona roller 2 Φ126X2700mm silicone corona roller;

Guide roller 2 Φ120X2700mm aluminum roller;

Corona value up to 38-42 dyne;

Flattening roller 1 piece of spreading rubber surface flattening roller;

Ozone removal Fully enclosed with ozone extraction interface, exhausted to the outdoors through a pipeline; exhaust fan power 2.2KW;

Control system Independent control cabinet, control system with alarm protection function;

11、Haul-off unit

Tractor drive 7.5KW variable frequency geared motor

Traction roller 1 Φ450X2800mm spiral runner roller, advanced internal runner design scheme makes the temperature error at both ends of the roller extremely small;

the surface of the roller is electroplated with hard chromium and then polished and polished;

the roller undergoes high-precision dynamic balance verification;

One rotary joint on the left and right;

Compression rubber roller 1 Φ300X2800mm compression rubber surface roller, the surface of the roller is covered with EPDM wear-resistant rubber treatment;

the roller has undergone high-precision dynamic balance verification;

dual-cylinder pneumatic opening and closing compression;

Guide roller 1 Φ120X2800mm aluminum guide roller, the surface of the roller is polished and hardened;

the roller undergoes high-precision dynamic balance verification;

12.Defect detection system

Brand origin: domestic high-quality brand

Effective detection width range 0-2500mm

Effective detection thickness range ≤1mm

Detection accuracy Required detection accuracy: 0.5m; test machine detection accuracy: 0.3m;

Types of flaw detection Black spots, impurities, foreign bodies, crystal spots, holes, etc. on the film surface

Guide roller 1 Φ120X2800mm aluminum guide roller, the surface of the roller is polished and hardened; the roller undergoes high-precision dynamic balance verification;

plan description

The system is composed of three parts: control host, machine vision system, and sound and light alarm system; it adopts image vision detection technology to realize real-time surface defect detection of high-speed running materials. The system uses a high-performance line scan camera to collect product surface images. If defects occur, they are processed through a special data processing board, including classification and positioning of defects, the output of alarms, and display of defect images.

13.Takeoff and Film cutting system

Traction drive 4KW frequency conversion gear motor

Traction roller 1 Φ175X2600mm spiral runner roller, advanced internal runner design scheme makes the temperature error at both ends of the roller extremely small; the surface of the roller is electroplated with hard chromium and then polished and polished; the roller undergoes high-precision dynamic balance verification; One rotary joint on the left and right;

Compression rubber roller 1 Φ160X2600mm compression rubber surface roller, the surface of the roller is covered with EPDM wear-resistant rubber treatment; the roller has undergone high-precision dynamic balance verification; dual-cylinder swing arm pneumatic opening and closing compression mechanism;

Flattening roller 1 piece of spreading rubber surface flattening roller

Transition guide rollers 2 Φ150X2600mm transition guide steel rollers, the surface of the roller is electroplated with hard chromium and then polished and polished; the roller has undergone high-precision dynamic balance verification;

Knife back rollers 2 Φ120X2600mm aluminum guide rollers, the surface of the roller is polished and hardened; the roller has undergone high-precision dynamic balance verification;

Film trimming and slitting use 3 sets of high wear-resistant ceramic blades, both sides are used for trimming, and the middle is used for slitting; the slitting spacing is convenient to adjust; the handwheel reducer controls the feed;

Edge material processing The edge trimming waste on both sides is sent to the waste treatment equipment by the air conveying pipeline; the power of the feeding fan is 3KW

Pressing and cutting moving device 0.75KW geared motor moves to open and close, high-precision linear guide rail ensures precise movement;

Guide roller 1 Φ120X2600mm aluminum guide roller, the surface of the roller is polished and hardened; the roller undergoes high-precision dynamic balance verification;

Tension feedback guide roller 1 Φ120X2600mm aluminum guide roller, the surface of the roller is polished and hardened; the roller undergoes high-precision dynamic balance verification; the roller support position has a tension monitoring feedback system;

Flattening roller 1 piece of spreading rubber surface flattening roller

Cut-off compression rubber roller 1 Φ200X2600mm compression anilox rubber roller, the roller is wrapped with EPDM wear-resistant rubber surface anilox

Processing of ventilation grooves; rollers have undergone high-precision dynamic balance verification; high-precision dual-cylinder floating control rubber rollers are compressed;

Membrane cutting system Pneumatic chopper type membrane cutting method, dual-cylinder drive; the tooth-shaped cutting knife is made of high-quality alloy knife steel material, sharp and durable; membrane cutting surface is clean;

14.Disc type double station winder

Winding method: disc type double station automatic turning and receiving

Flip drive 7.5KW frequency conversion gear motor system drive

Maximum winding diameter Φ600mm

Winding drive 2 sets of 5.5KW frequency conversion gear motor system drive

Tension control Cone automatic tension control

Static elimination Use the static rope to eliminate static electricity

Follow-up guide rollers 2 Φ120X2500mm aluminum guide rollers, the surface of the roller is polished and hardened; the roller undergoes high-precision dynamic balance verification;

Rewinding deviation correction: The rewinding machine motor drives the swing correction; the swing range is 50-100mm;

Unloading method Cylinder drive clamping loosens, easy unloading

Air expansion shaft specifications 3 inches air expansion shaft; the equipment is equipped with a total of 3 air expansion shafts, 2 work, and 1 replacement;

15.On-line scrap recycling system

Edge material recovery method After the edge material is collected by the blade, it is blown to the hopper of the extrusion host

Crushing motor power 11KW

Conveying fan power 5.5KW

Conveying and feeding Φ110mmSUS304 stainless steel pipe overhead conveying, 0.75KW screw feeder forced feeding

16.Electrical control system

The production line adopts the fourth-generation software technology control system of JWELL dedicated to breathable membranes. The latest intelligent distributed control scheme, man-machine interface, can be a jog, can also be linked across the whole line, main engine, auxiliary machine, traction synchronous control, programmable and set all levels of alarm and protection functions. One-key setting, high precision of speed adjustment, precise single linkage control of extruder and production line; tension controller plus tension closed-loop adjustment, automatic tracking of the whole machine speed; with melt pressure and melt temperature measurement functions; host heating zone heating Use high quality.

Brand solid-state relay control; the production line is controlled by a mobile Siemens SIEMENS or Austria B&R’s exquisite man-machine interface true color display, and the temperature control is modular; the host inverter is driven by INOVANCE; the large screen digital displays the production line speed;

After-sale service

1.The guarantee period is 1 year and service is available lifelong. The cost caused by the seller’s expert in the customer’s country (including shuttle trip ticket between China and the Buyer’s, inland traffic, medical fees, lodging, dinner, and so on) and the cost of the materials of the components will be covered by the buyer, but during the guarantee period, the cost of the components (quick-wear parts and human improper use are not included) will be covered by the seller.

2.Under the right operation method and recommended raw material, the quantities screw and the barrel is for one year.

3.Our expert will answer any inquiry within 24-48 hours and it will be solved as soon as possible.

4.The customer can send the engineer to our JWELL with training.

5.The Seller supplies the complete technical support documents and the relative drawings of the electric components written in Chinese and English.

6.The seller can send enough technicians to the Buyer’s company for installation and testing of the lines.

7.List of the spare parts (Please see the list of spare parts).

FAQ

- International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

- Terms of Payment: LC, T/T

- Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months

- Number of Foreign Trading Staff:>50 People

Yes, We own 5 manufacturing bases and sales center in Shanghai , Suzhou ,Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo.After more than 40 years development,

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with

International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously

imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification,

IS09001 and 2008 quality management system . And we have 12 months quality warranty time. We testing the

machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and

Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical

innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea

to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest

port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing

engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing,

operation and maintenance service for a life time.

Certificates

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:SGS

extrusion down stream equipment

Certified By:Other

Design, Development, Manufacture and Sales of intellectual property rights management for Plastic Machine

Certified By:Other

Design, Development, Manufacture and Sales of Plastic Pipe and Sheet Extrusion Production Line

Certified By:Quality Austria Training, Certification and Evaluation Ltd

Plastic extrusion line