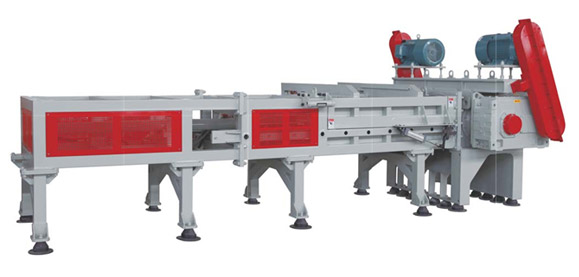

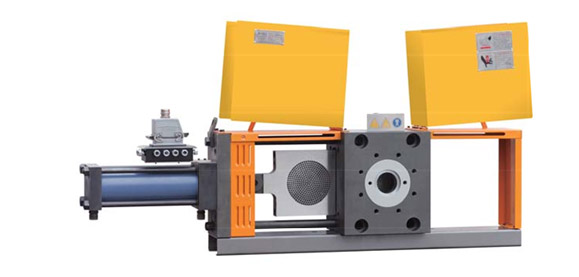

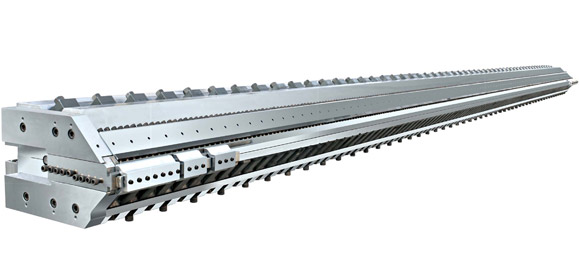

Popular Design for Машина Для Экструзии Труб Из Пвх - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Global Plastics Extrusion Market CAGR 2018 – Swot Analysis, Porters Five Forces Analysis, Forecast Till 2023 | Производственная Линия Ppr

Пыльным мешком по голове “Дальневосточная газета Золотой Рог” | Extruded Plastic Tubing

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of Popular Design for Машина Для Экструзии Труб Из Пвх - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Guatemala , UK , France , Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we've got got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!

-

Good User Reputation for Приводной Экструдер - ...

-

China Factory for Plastic Pvc U Profile With Ex...

-

Hot Selling for Monofilament Yarn Extruder Mach...

-

China Manufacturer for Recycling Extruder - Ho...

-

Free sample for Tpu Film Lamination Machine - ...

-

2017 China New Design Plastic Extrusion Industr...