PriceList for Side Feeder Twin Screw Extruder - Hollow Cross Section Plate Die Series – Jwell Detail:

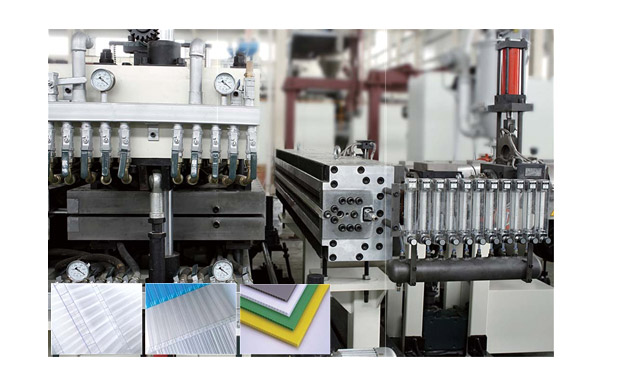

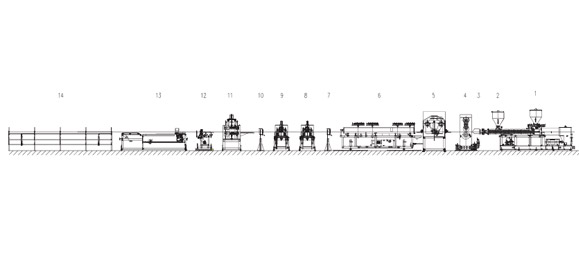

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

В 2017 г рост эффективности производства на Московском НПЗ обеспечил экономический эффект в 1,3 млрд руб // В тренде // Новости | Wpc Extrusion Machine

Extruders and Compounding Machines Market by top Key Vendors, Trends, Sales, Supply, Demand, Analysis and Forecasts to 2025 | Производственная Линия Ppr

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for PriceList for Side Feeder Twin Screw Extruder - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Brunei , Tunisia , Burundi , Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

-

Best Price for Production Line Of Cable Filler ...

-

Professional Design Трубопроводная Экструзионна...

-

Hot sale Factory Custom Plastic Hollow Extrusio...

-

Super Purchasing for High Strength Aluminum Pla...

-

Low price for Машина Для Производства Пластиков...

-

China Manufacturer for Plastic Bag Making Machi...