Short Lead Time for Компаундирующая Экструзионная Машина - Biaxially Oriented Die – Jwell Detail:

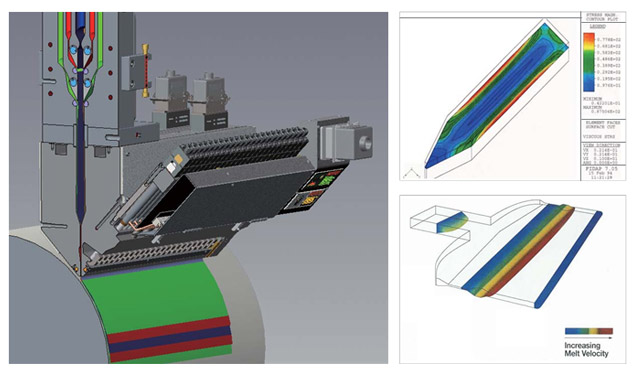

Biaxially Oriented Die

Product detail pictures:

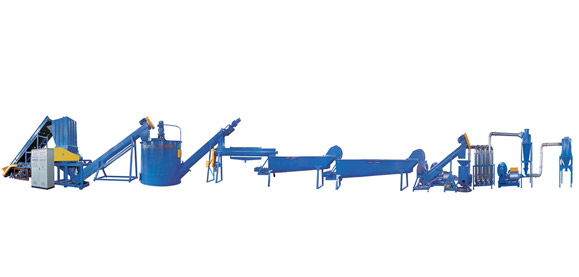

Related Product Guide:

Coextrusion Line Demonstrates Technology for API Catheters : Plastics Technology | Screw Extruder Machine

Can an audiophile find joy in an under $100 amplifier? | Screw Extruder Machine

We believe that prolonged expression partnership is really a result of top of the range, value added support, rich encounter and personal contact for Short Lead Time for Компаундирующая Экструзионная Машина - Biaxially Oriented Die – Jwell, The product will supply to all over the world, such as: Macedonia , Lithuania , Tanzania , We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

-

New Delivery for Foam Making Machine - DYQT Se...

-

2017 China New Design Ic Tube Making Machine - ...

-

factory low price Counterrotating Twin Screw Ex...

-

2017 Latest Design Splitfilm Extruder - VDYPS...

-

Rapid Delivery for Sintered Filter Disc - VDY...

-

Factory directly supply Twin Screw Extruder Par...