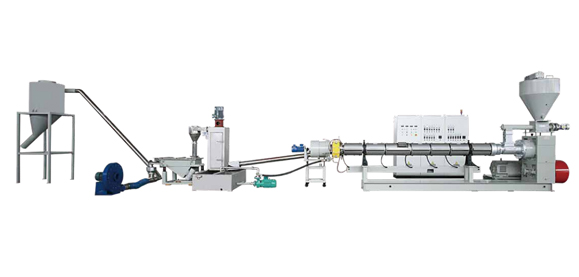

Short Lead Time for Mixing Machine Price - Film Die Series – Jwell Detail:

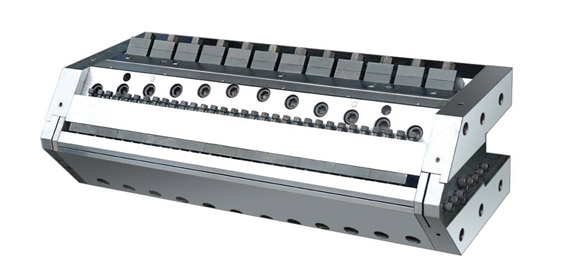

Film Die Series

Product detail pictures:

Related Product Guide:

Выключить из сети все электроприборы необходимо в ночь на воскресенье | Производственная Линия Ppr

Natvar to showcase extruded products portfolio at MD&M East | Extruded Plastic Tubing

Our primary target will be to provide our clients a serious and responsible small business relationship, supplying personalized attention to all of them for Short Lead Time for Mixing Machine Price - Film Die Series – Jwell, The product will supply to all over the world, such as: Miami , Washington , Kuwait , The quality of our merchandise is equal to OEM's quality, because our core parts are the same with OEM supplier. The above items have passed professional certification, and we not only can produce OEM-standard items but we also accept Customized Merchandise order.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

Discount wholesale Extruder For Plastic Pvc - ...

-

Fast delivery Masterbatch Plastic Extruder Pric...

-

OEM Factory for Nrm Экструдер - RTP Composite ...

-

Ordinary Discount Wooden Plastic Board Extrusio...

-

High Quality Single Screw Extruder Suppliers - ...

-

Excellent quality Single Screw Straw Extrusion ...