Special Design for Single-screw Extruder Machine - Hollow Cross Section Plate Die Series – Jwell Detail:

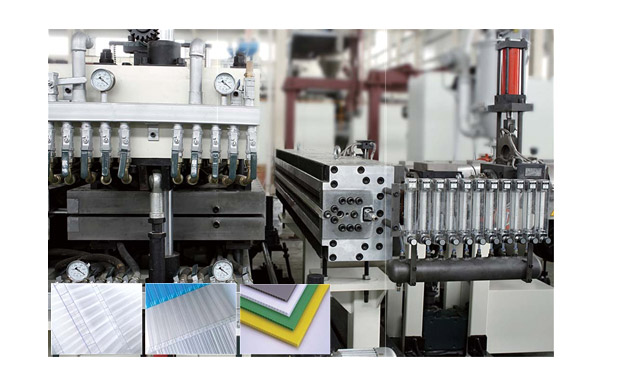

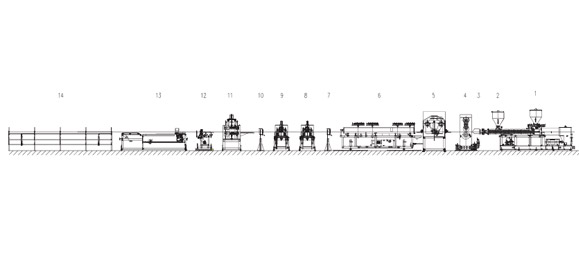

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Twin-Screw Extruder Market In Depth 2018 -2025 Size, Growth And Swot Analysis By Key Players: Matila, Toshiba Machine, Flytech, Xtrutech, Coperion | Screw Extruder Machine

Centerville, GA’s Sunbelt Plastic Extrusion to close | Wpc Extrusion Machine

Our primary target will be to provide our clients a serious and responsible small business relationship, supplying personalized attention to all of them for Special Design for Single-screw Extruder Machine - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Armenia , Slovak Republic , Estonia , Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

-

Factory wholesale Single Screw Machine - JWZ-B...

-

OEM/ODM Manufacturer Hand Extruder - Main Tech...

-

High Performance Pvc Plastic Pipe Screw Extrude...

-

Fast delivery Twin Screw Extruder Twin Screw Ex...

-

Fixed Competitive Price Customized Plastic Abs ...

-

Best Price on Plastic Extrusion Screw Design - ...