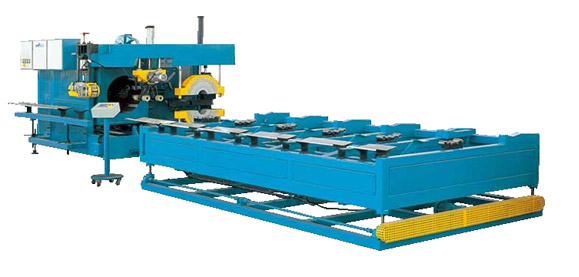

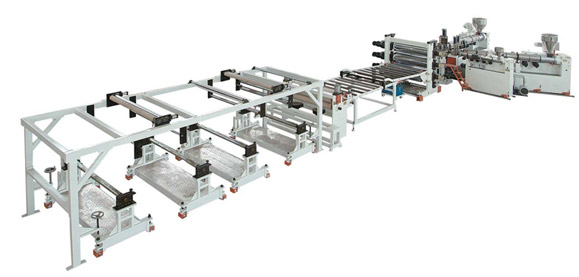

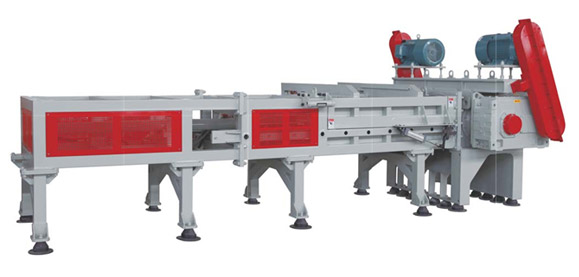

Trending Products Twin Screw Ldpe Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Forest Twin Screw Extruders Market Evolving Industry Trends and Key Insights by 2024 | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

How microextrusion medical tubing is leading to new procedures | Wpc Extrusion Machine

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for Trending Products Twin Screw Ldpe Extruder - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: Mauritania , panama , Ecuador , Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

-

Well-designed Размеры Винтовых Колпачков - UPV...

-

Massive Selection for Single Screw Barrel For F...

-

New Fashion Design for Plastic Electric Box - ...

-

Professional Design Extruder Single Feed Screw ...

-

China Gold Supplier for Ps Profile Extrusion Li...

-

Wholesale Dealers of Xq Sj-45 Single Screw Extr...