Well-designed Extruding Plastic Garbage Bag Machine Price - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell Detail:

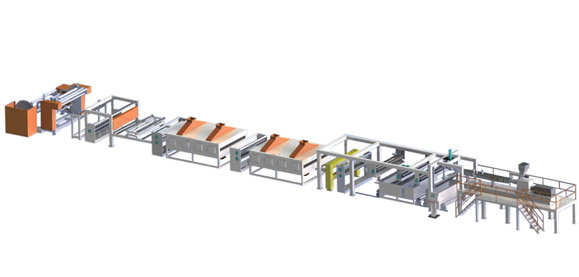

XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology)

Product detail pictures:

Related Product Guide:

Роснефть опровергла проблемы на ледостойкой добывающей платформе «Орлан» в Охотском море // Происшествия // Новости | Extruded Plastic Tubing

Газпром нефть открыла в г Омске инженерный центр по испытанию катализаторов собственного производства // Переработка // Новости | Производственная Линия Ppr

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for Well-designed Extruding Plastic Garbage Bag Machine Price - XPS Heat Insulation Foaming Boad Extrusion Line (CO2 Foaming Technology) – Jwell, The product will supply to all over the world, such as: New Zealand , United States , Madrid , The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we will continue with the most professional and high quality service to provide the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

-

Discountable price Air Bubble Film Making - Sc...

-

Factory source Plastic Granules Making/cutting ...

-

2017 Latest Design Single Screw Extrusion Machi...

-

100% Original Factory Recycled Plastic Pelletiz...

-

18 Years Factory Shantou Extrusion Machine - P...

-

Leading Manufacturer for Разница Между Одношнек...