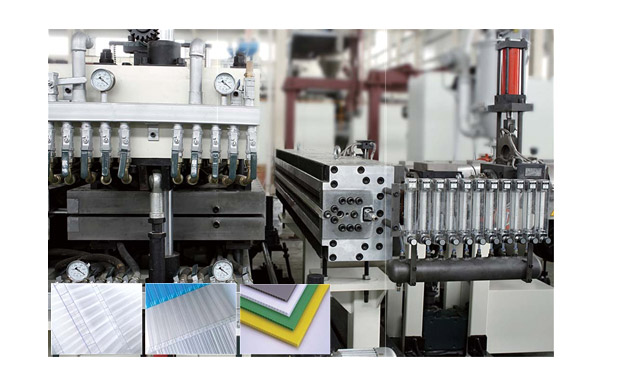

Well-designed Yarn Extrusion Machine - Hollow Cross Section Plate Die Series – Jwell Detail:

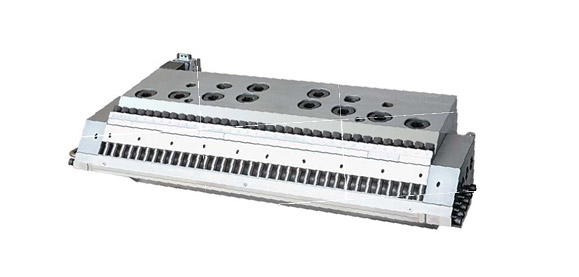

Hollow Cross Section Plate Die Series

Product detail pictures:

Related Product Guide:

Latest mechanical, hydraulic and screw extrusion presses for briquetting applications available from Briquetting Systems | Производственная Линия Ppr

Shop Online for ‘Off-the-Shelf’ Medical Tubing : Plastics Technology | Экструзия/Поточная Линия Из Гофрированной Плитки Из Пвх

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Well-designed Yarn Extrusion Machine - Hollow Cross Section Plate Die Series – Jwell, The product will supply to all over the world, such as: Portland , The Swiss , San Diego , We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

-

Cheapest Price Pvc Profile For Wardrobe Edge De...

-

Cheapest Price Conical Twin Screw And Barrel - ...

-

OEM China Co Extrusion Process - Single Layer ...

-

Low MOQ for Extrusion Die Design - Sheet Die S...

-

Special Design for Pvc Profile Window Price - ...

-

Good Wholesale Vendors Plastic Sheet Extrude Ma...